Disc Granulator

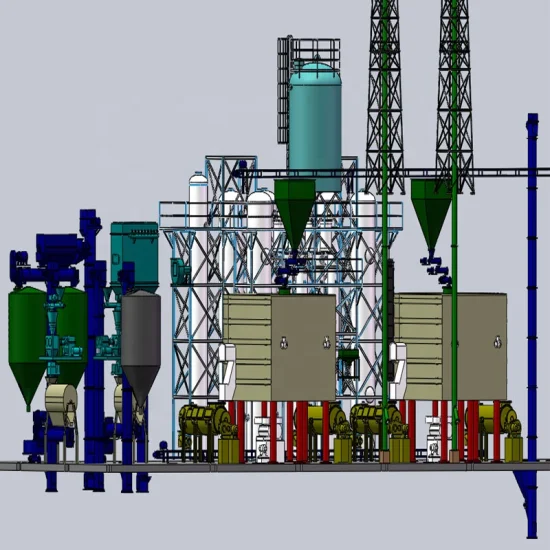

Disc granulator is a commonly used industrial machinery equipment, widely used in the fertilizer industry, mainly used to convert powdered or granular raw materials into granular products through compression and granulation processes. The disc granulator is a type of granulator lined with high-strength fiberglass, which has the advantages of uniform granulation, high granulation rate, smooth operation, sturdy and durable equipment, and long service life.

Characteristic

The disc granulator adopts an integral circular arc structure, with a granulation rate of over 93%. There are three discharge ports to facilitate intermittent production operations, reduce labor intensity, and improve labor efficiency. The reducer and motor are driven by flexible belts, which ensures smooth starting, reduces impact force, and improves equipment service life. The bottom of the granulation disc is reinforced with multiple radiating steel plates, which are sturdy, durable, and never deform. Thickened, weighted, and sturdy base design, no need for anchor bolts to fix, smooth operation.

Composition structure

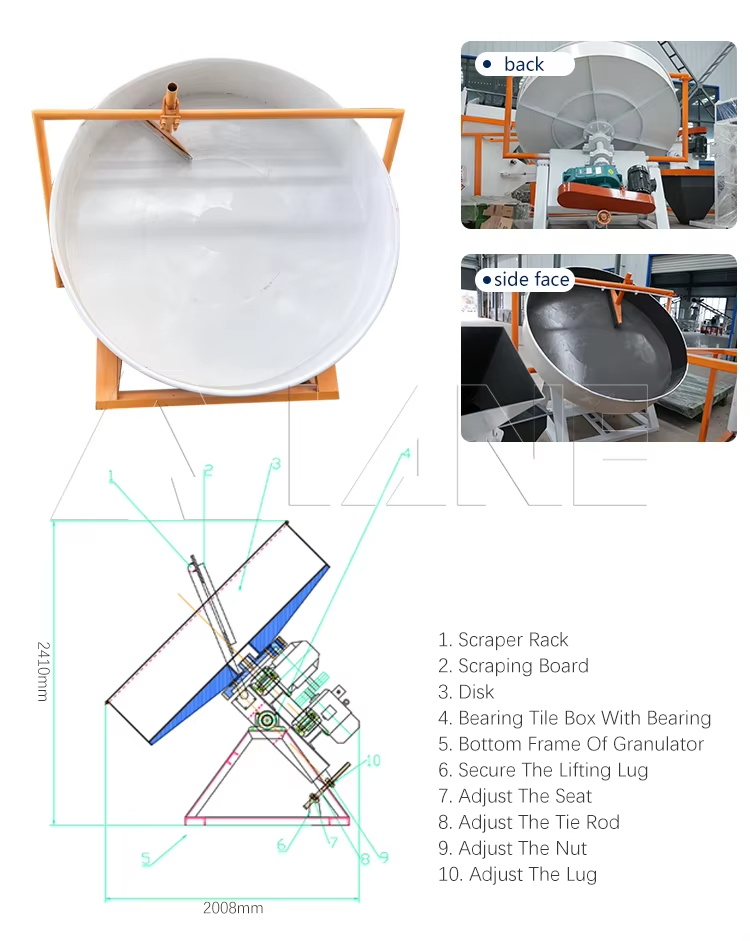

Main body: including the frame, adjustment part, and granulation disc structure.

Transmission part: One main reducer, with a pulley installed on the input shaft and a small gear installed on the output shaft; One main motor, equipped with one pulley; Supporting granulation disc device, including one main shaft, two sets of roller bearings, and two bearing seats.

Auxiliary parts: scraper holder, non powered scraper, etc.

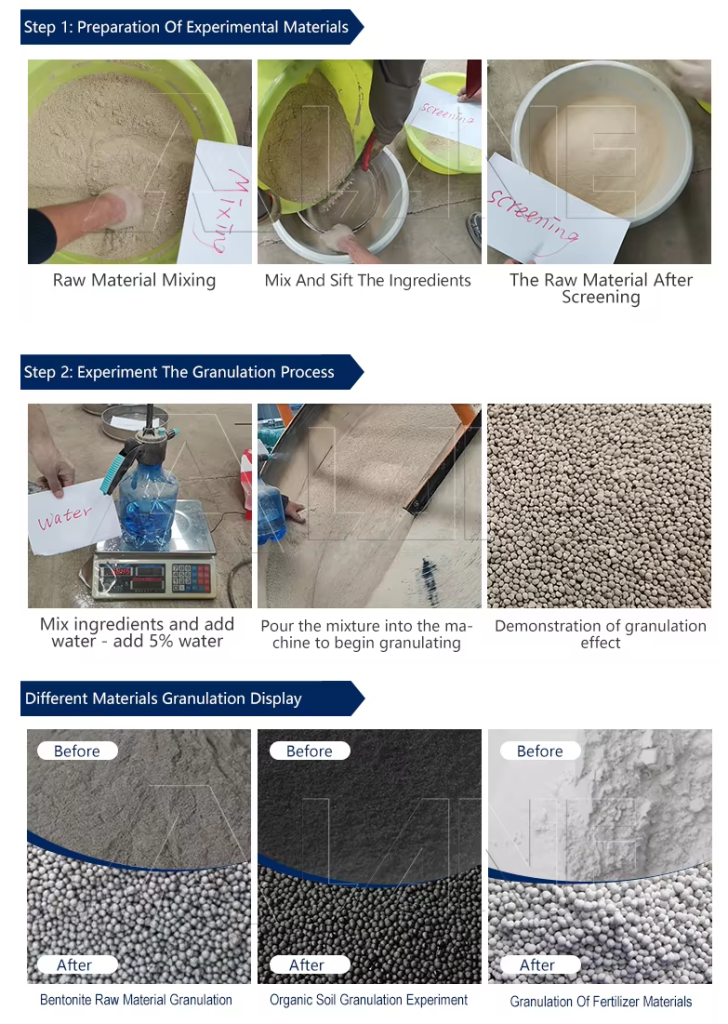

Working process

Material feeding: Various dry powder materials are added from the top of the equipment, subjected to degassing, spiral pre compression, and transported to the arc-shaped slots of two rolling mills.

Material compression: Two rollers rotate at the same speed and in opposite directions, biting the material into the groove and performing forced compression.

Material Forming: After passing through the compression zone, the pressure on the material gradually decreases, and its surface tension and gravity cause it to naturally detach and enter the crusher and granulator for crushing and finishing.

Finished product processing: Then it enters the vibrating screen for screening. Qualified products are sent to the finished product warehouse or directly packaged through the conveyor. The material under the powder screen is sent back to the raw material warehouse for secondary rolling through the return device.

Advantage

Wide applicability: The disc granulator is widely used for processing spherical particles of bio organic fertilizers, such as coal powder, cement, clinker, fertilizers and other materials.

High production efficiency: The disc granulator can achieve continuous production with high production efficiency, suitable for large-scale production needs.

Easy to operate: The disc granulator has a simple structure, is easy to operate, and is easy to maintain and clean.

Environmental protection and energy saving: The disc granulator has no drying process, granulation at room temperature, one-time molding, low investment, fast results, and good economic benefits. The power is small, the operation is reliable, there are no emissions of three wastes, the operation is stable, the maintenance is convenient, the process layout is reasonable, the technology is advanced, and the production cost is low.

Overall, disc granulators play an important role in industrial production due to their efficient production capacity, wide range of applications, and environmentally friendly and energy-saving characteristics.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!