Rotary drum churning teeth two-in-one granulator

The Rotary drum churning teeth two-in-one granulator is a device that integrates mixing and granulation functions, suitable for granulation of various powdered or small granular materials. It adopts advanced production processes and technologies, which can efficiently convert materials into high-quality granular products. The Rotary drum churning teeth two-in-one granulator is suitable for the production of organic fertilizers and NPK fertilizers. It has strong granulation ability and is suitable for granulation of organic fertilizers, organic-inorganic compound fertilizers, bio organic fertilizers, and other fertilizers.

Composition structure

The Rotary drum churning teeth two-in-one granulator mainly consists of the following parts:

Feeding system: responsible for conveying the materials to be pelletized to the interior of the equipment.

Mixing system: composed of multiple high-speed rotating mixing teeth, it thoroughly stirs and mixes the materials.

Granulation system: By using specific molds and pressure devices, the mixed material is compressed into granules.

Discharge system: Transport the pelletized material to the outside of the equipment.

Control system: used to control the operating status and parameter settings of equipment.

Working process

The working process of the Rotary drum churning teeth two-in-one granulator mainly includes the following steps:

Feed: Transport the material to be granulated into the equipment through the feed system.

Stirring: The stirring teeth in the stirring system begin to rotate at high speed, thoroughly stirring and mixing the materials.

Granulation: During the mixing process, the material is gradually extruded into granules and formed through the molds and pressure devices of the granulation system.

Discharge: After granulation is completed, the discharge system transports the granular material to the outside of the equipment.

Advantage

The Rotary drum churning teeth two-in-one granulator has the following advantages:

High production efficiency: By using high-speed rotating stirring teeth and advanced production technology, materials can be efficiently converted into granules.

Good product quality: Through thorough mixing and blending, as well as precise mold and pressure control, the quality and stability of granular materials are ensured.

Wide applicability: Suitable for granulation of various powdered or small granular materials, such as chemical raw materials, pharmaceutical intermediates, food additives, etc.

Easy to operate: The device has a simple structure, is easy to operate, and is easy to maintain and clean.

Environmental protection and energy conservation: There will be no harmful substance emissions during the production process, which meets environmental protection requirements; Simultaneously adopting energy-saving technologies to reduce energy consumption.

High degree of automation: Equipped with advanced control systems, it can achieve automated production and remote monitoring, improve production efficiency and management level.

Of course, we also offer other types of products for your different needs, you can click to view.

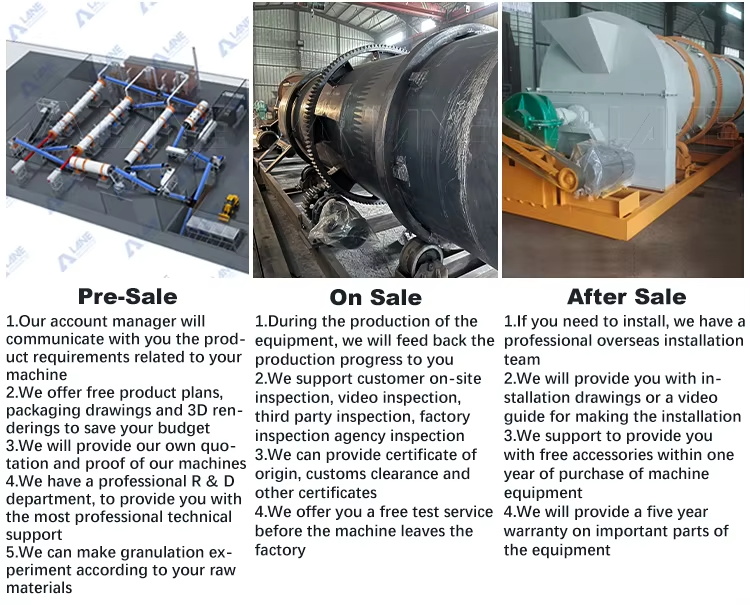

For more information, please contact us by sending an inquiry today! We can help you!