Double Shaft Gravityless Free Mixer

Double Shaft Gravityless Free Mixer is a device that uses two mixing shafts to mix materials. Compared with traditional single-shaft mixers, double-shaft gravityless mixers have higher mixing efficiency and better mixing effect. It forms a gravityless state in the barrel through the reverse rotation of two mixing shafts, thereby achieving rapid and uniform mixing. It is widely used in the mixing of various powdered and granular materials, such as cement, sand, stone powder, feed, etc.

The design of Double Shaft Gravityless Free Mixer allows the material to form a gravityless state in the barrel, thereby avoiding the accumulation and agglomeration of materials and improving the uniformity of mixing. It is widely used in fertilizer, chemical, building materials, feed, food and other industries. The following is a detailed description of the introduction, composition structure, working process and advantages of Double Shaft Gravityless Free Mixer.

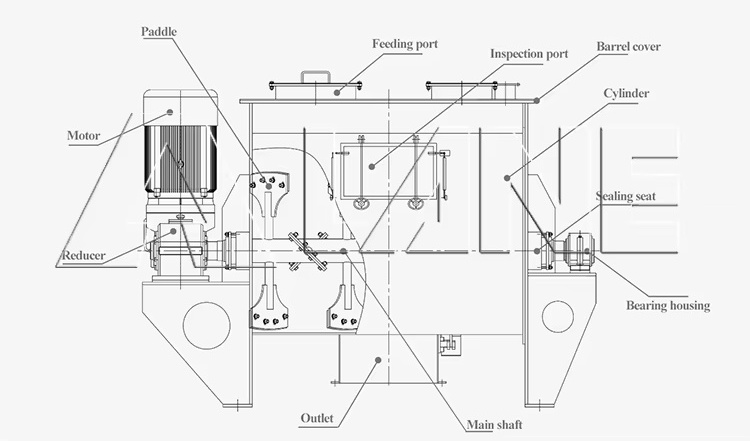

Composition Structure

Mixing barrel: The main part of Double Shaft Gravityless Free Mixer is usually made of high-quality steel with sufficient strength and wear resistance. The shape and size of the barrel are customized according to actual needs to meet different production and mixing requirements.

Mixing shaft: two rotating parts installed inside the cylinder, used to mix and stir the materials. The mixing shaft is usually made of high-strength steel, and the surface is specially treated to improve wear resistance and corrosion resistance.

Mixing blade: a part installed on the mixing shaft, used to shear, squeeze and flip the material. The shape and number of the mixing blades are designed according to the properties of the material and the mixing requirements to achieve the best mixing effect.

Motor and reducer: a device that provides power to the mixing shaft, and converts the high-speed rotation of the motor into the low-speed rotation of the mixing shaft through the reducer to meet the mixing speed requirements under different process conditions.

Sealing device: a device used to prevent material leakage and external impurities from entering the cylinder. The sealing device usually adopts the form of mechanical seals or packing seals to ensure the sealing performance and service life of the equipment.

Control system: a system used to control the operating status and parameters of the Double Shaft Gravityless Free Mixer. The control system usually includes instruments and controllers such as temperature sensors, pressure sensors, and liquid level sensors, which can realize automatic control and remote monitoring.

Working Process

Feeding: The materials to be mixed are put into the barrel of Double Shaft Gravityless Free Mixer in a certain proportion. Due to the design of the barrel, the materials can flow freely in it, which is conducive to improving the mixing efficiency.

Stirring: Start the motor and reducer to drive the two stirring shafts to rotate in opposite directions in the barrel. The materials are sheared, squeezed and turned under the action of the stirring blades to form a zero-gravity state. In this state, the friction between the materials is greatly reduced, which is conducive to improving the uniformity of mixing.

Heating/cooling: According to the process requirements, the materials in the Double Shaft Gravityless Free Mixer are heated or cooled. Heating usually adopts electric heating or steam heating, and cooling adopts water cooling or air cooling. In the zero-gravity state, the materials are heated or cooled more evenly, which is conducive to improving the product quality.

Discharging: When the materials are mixed evenly and reach the expected temperature and pressure conditions, the materials are discharged from the Double Shaft Gravityless Free Mixer through the discharging port. During the discharging process, the discharging speed and discharging amount can be controlled manually or automatically. Since the material has better fluidity in a zero-gravity state, the discharging process is also smoother.

Cleaning and maintenance: After each use, the Double Shaft Gravityless Free Mixer needs to be cleaned and maintained to ensure the cleanliness and integrity of the equipment. Since the design of the barrel and the mixing blades makes it easier to clean the material, cleaning and maintenance work is also more convenient.

Advantages

High mixing efficiency: The Double Shaft Gravityless Free Mixer forms a zero-gravity state in the barrel through the reverse rotation of the two mixing shafts, thereby greatly improving the mixing efficiency. In this state, the friction between the materials is greatly reduced, which is conducive to improving the uniformity of mixing.

Wide range of applications: The double-shaft gravityless mixer is suitable for mixing various powdered and granular materials, such as cement, sand, stone powder, feed, etc. It is widely used in chemical, building materials, feed, food and other industries to meet the process requirements of different industries.

Simple structure: The Double Shaft Gravityless Free Mixer has a relatively simple structure, is easy to operate, and is easy to maintain and maintain. At the same time, it has good sealing performance, which can prevent material leakage and external impurities from entering the barrel.

Energy saving and environmental protection: Double Shaft Gravityless Free Mixer adopts advanced mixing technology and energy-saving design, which can reduce energy consumption and emissions and meet environmental protection requirements. At the same time, its mixing efficiency is high, which can reduce energy waste.

Easy to operate: Double Shaft Gravityless Free Mixer is easy to operate and can realize automatic control and remote monitoring, improve production efficiency and management level. At the same time, its discharging process is also smoother, which is conducive to improving production efficiency.

In summary, Double Shaft Gravityless Free Mixer has become one of the indispensable equipment in many industrial production processes with its excellent performance and wide range of applications.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!