Stainless steel horizontal mixing tank

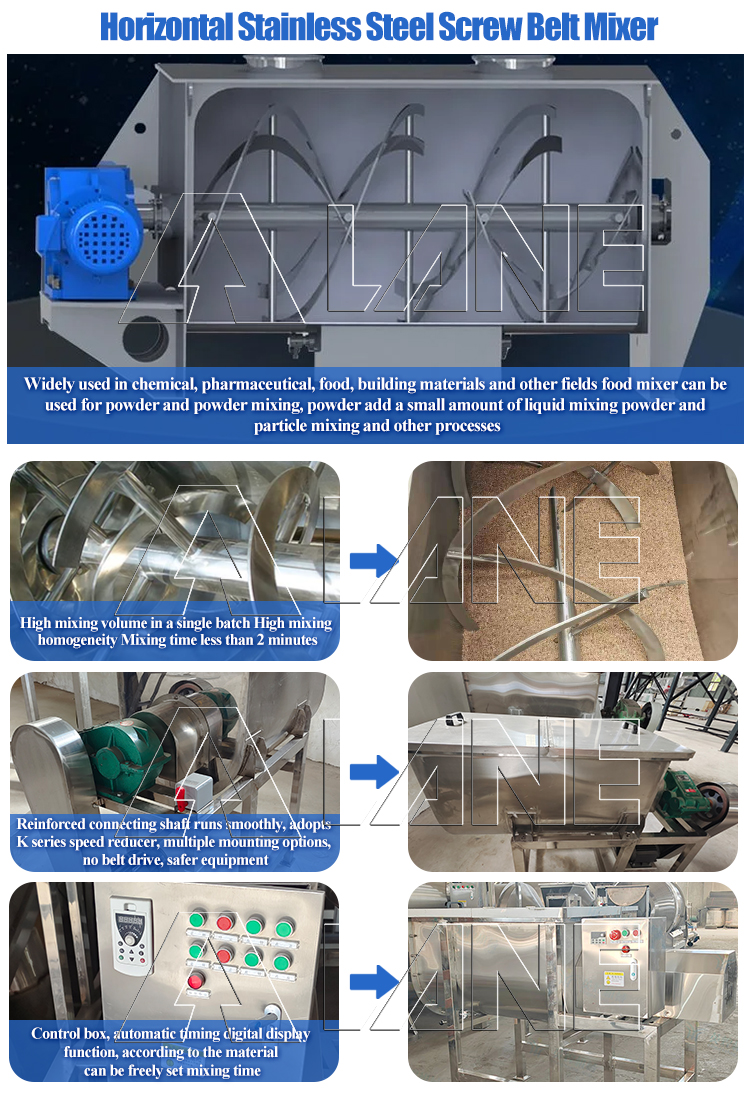

Stainless steel horizontal mixing tank is a container used for mixing, reacting, and storing liquids or gases, usually made of stainless steel. Compared with vertical mixing tanks, horizontal mixing tanks have better mixing effects and higher volume utilization. It is widely used in chemical, pharmaceutical, food and other industries, and has the advantages of corrosion resistance, high temperature resistance, and easy cleaning. With its excellent corrosion resistance, high strength and easy cleaning, it has become one of the indispensable equipment in many industrial production processes. The following is a detailed description of the introduction, composition structure, working process and advantages of stainless steel horizontal mixing tank.

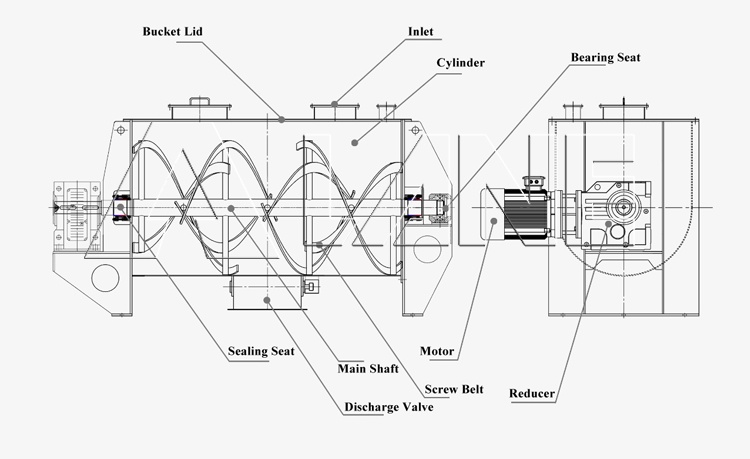

Composition Structure

Tank body: The main part of the stainless steel horizontal mixing tank, usually made of high-quality stainless steel material, has good corrosion resistance and strength. The shape and size of the tank body are customized according to actual needs.

Agitator: A rotating component installed inside the tank body, used to stir and mix the materials. The shape and speed of the agitator can be adjusted according to the process requirements.

Motor and reducer: A device that provides power to the agitator. The high-speed rotation of the motor is converted into the low-speed rotation of the agitator through the reducer to meet the stirring speed requirements under different process conditions.

Sealing device: A device used to prevent material leakage and external impurities from entering the tank body. The sealing device usually adopts the form of mechanical seal or packing seal.

Support: The component that supports the entire mixing tank is usually made of carbon steel or stainless steel, with good stability and load-bearing capacity.

Control system: A system used to control the operating status and parameters of the mixing tank. The control system usually includes instruments and controllers such as temperature sensors, pressure sensors, and liquid level sensors, which can realize automatic control and remote monitoring.

Working Process

Feeding: The materials to be mixed are added to the mixing tank in a certain proportion. Due to the design of the stainless steel horizontal mixing tank, the materials can be more evenly distributed in the tank, which is conducive to improving the mixing effect.

Stirring: Start the motor and reducer to drive the agitator to rotate in the tank body to stir and mix the materials. During the stirring process, the mixing effect of the materials can be changed by adjusting the shape and speed of the agitator. At the same time, the design of the horizontal mixing tank enables the materials to form a better flow state in the tank, which is conducive to improving the mixing efficiency.

Heating/cooling: According to the process requirements, the materials in the mixing tank are heated or cooled. Heating usually adopts electric heating or steam heating, and cooling adopts water cooling or air cooling. In the horizontal mixing tank, the heating and cooling effects are more uniform due to the more uniform distribution of materials.

Discharging: When the materials are evenly mixed and reach the expected temperature and pressure conditions, the materials are discharged from the mixing tank through the discharge port. During the discharging process, the discharging speed and amount can be controlled manually or automatically. Due to the design of the horizontal mixing tank, the materials can also maintain good fluidity during discharging, which is conducive to improving the discharging efficiency.

Cleaning and maintenance: After each use, the mixing tank needs to be cleaned and maintained to ensure the cleanliness and integrity of the equipment. Since the design of the horizontal mixing tank makes it easier to clean out the materials, cleaning and maintenance work is also more convenient.

Advantages

Good mixing effect: The design of the stainless steel horizontal mixing tank makes the materials more evenly distributed in the tank, which is conducive to improving the mixing effect. At the same time, the shape and speed of the agitator can also be adjusted according to the process requirements to meet different mixing requirements.

High volume utilization: Compared with the vertical mixing tank, the horizontal mixing tank has a higher volume utilization. This means that under the same floor space, the horizontal mixing tank can accommodate more materials, thereby reducing production costs.

Strong corrosion resistance: Stainless steel has good corrosion resistance and can resist the erosion of various chemical substances. It is suitable for mixing and storing various corrosive media.

High strength: Stainless steel has high strength and hardness, can withstand large pressure and impact loads, and ensure the stability and safety of the equipment.

Easy to clean: The surface of stainless steel is smooth and flat, not easy to adhere to materials, easy to clean, and conducive to keeping the equipment clean and hygienic.

Wide range of applications: Stainless steel horizontal mixing tank is suitable for mixing and storing liquids or gases of various viscosities, and can meet the process requirements of different industries.

Energy saving and environmental protection: Stainless steel horizontal mixing tank adopts advanced mixing technology and energy-saving design, which can reduce energy consumption and emissions and meet environmental protection requirements.

Easy operation: Stainless steel horizontal mixing tank has a simple structure and easy operation. It can realize automatic control and remote monitoring, improve production efficiency and management level.

In summary, stainless steel horizontal mixing tank has become one of the indispensable equipment in many industrial production processes with its excellent performance and wide range of applications.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!