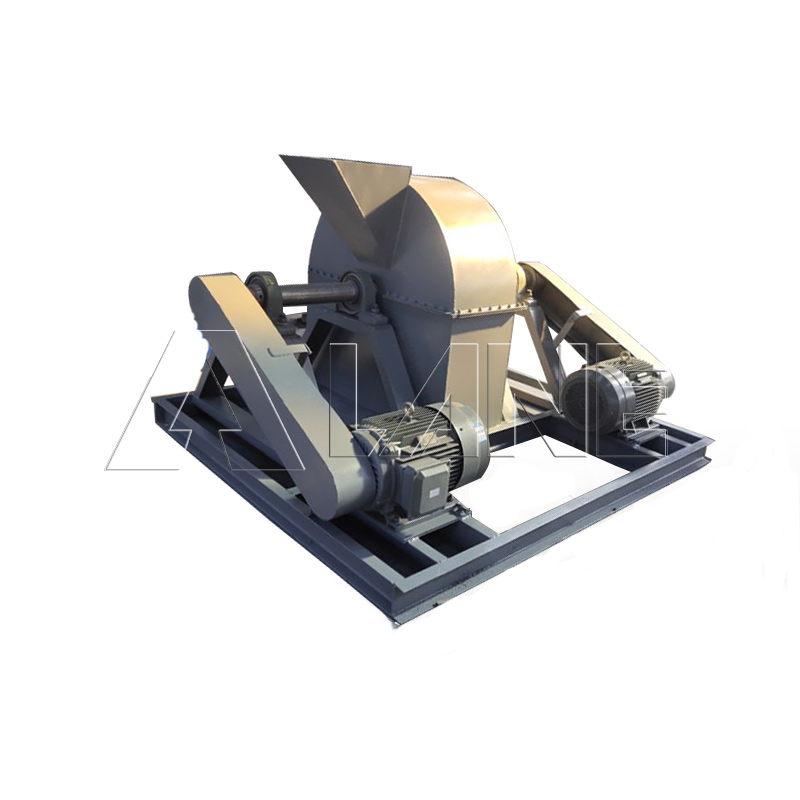

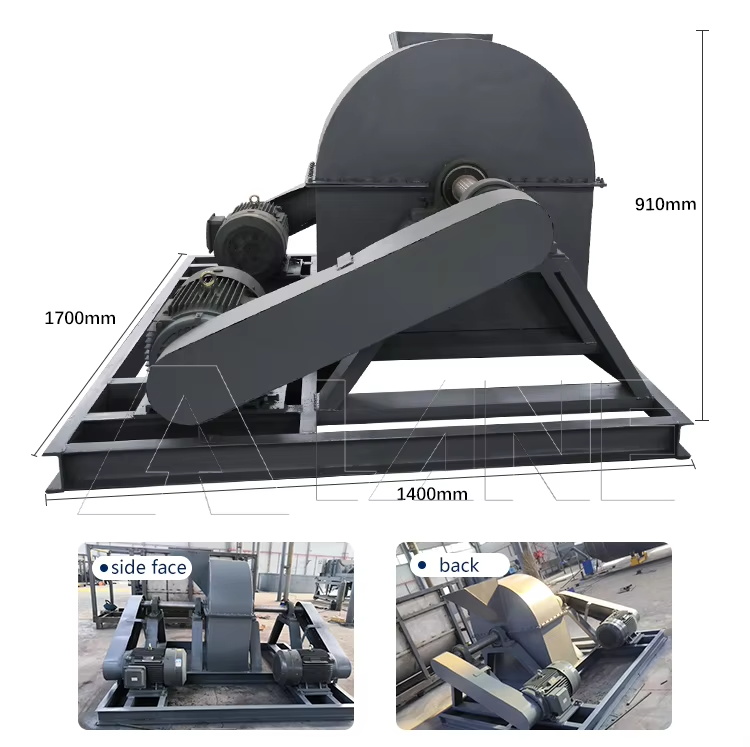

Cage Crusher

Cage crusher, also known as cage mill or cage crusher, is an efficient crushing equipment widely used in fertilizer, mining, metallurgy, building materials and other industries. It uses the high-speed rotating cage rotor to impact and shear the material, breaking the large pieces of material into small pieces or powder to meet the needs of different industries. The following is a detailed description of the introduction, composition structure, working process and advantages of cage crusher.

Introduction

Cage crusher is a crushing equipment that uses a high-speed rotating cage rotor to impact and shear the material. It can handle materials of various hardness and humidity, and has the characteristics of high crushing efficiency, low energy consumption, and uniform product particle size.

Composition Structure

Cage rotor: The core component of the cage crusher, composed of multiple cage bars, is cylindrical. The cage bars are usually made of highly wear-resistant materials and can withstand high-speed rotation and material impact. The cage rotor rotates at high speed driven by the motor to impact and shear the material entering the crushing chamber.

Crushing chamber: A cavity located outside the cage rotor, used to hold the material to be crushed. The crushing chamber is usually made of wear-resistant steel plates, which can withstand the impact and wear of materials. The shape and size of the crushing chamber can be adjusted according to different needs to meet the crushing requirements of different materials.

Feed port: An opening located at the top of the crushing chamber, used to add materials to be crushed into the crushing chamber. The feed port is usually equipped with an adjustment device to control the feed speed and feed amount to ensure the stability and continuity of the crushing process.

Discharge port: An opening located at the bottom of the crushing chamber, used to discharge the crushed materials. The discharge port is usually equipped with a screen or a grate plate to control the size and shape of the discharge particle size. According to needs, the discharge port can be equipped with multiple screens or grate plates of different specifications to achieve multi-stage crushing and screening.

Transmission system: It includes components such as motors, reducers and belts, which are used to drive the rotation of the cage rotor. The rationality of the design of the transmission system directly affects the performance and stability of the cage crusher. Therefore, when selecting the transmission system, many factors need to be considered, such as motor power, reducer type, belt material, etc.

Lubrication system: It is used to lubricate and cool components such as the transmission system and bearings. The lubrication system can be lubricated by grease or thin oil, and the specific choice depends on the use environment and requirements of the equipment. A good lubrication system can reduce the wear and failure rate of the equipment and extend the service life of the equipment.

Control system: used to control the start, stop, feeding, discharging and other operations of the cage crusher. The control system can be controlled manually or automatically, and the specific choice depends on the scale and degree of automation of the equipment. Advanced control systems can achieve remote monitoring and intelligent management, and improve the operating efficiency and safety of the equipment.

Working Process

Feeding: The material to be crushed enters the crushing chamber through the feed port. The feeding speed and feed amount can be controlled by the adjustment device to ensure the stability and continuity of the crushing process.

Crushing: The cage rotor rotates at high speed driven by the motor, and impacts and shears the material entering the crushing chamber. Due to the special shape and arrangement of the cage bars, the material is subjected to multiple impacts and shearing during the crushing process, and is gradually broken into small pieces or powder. At the same time, the materials in the crushing chamber will also collide and rub against each other, further promoting the crushing effect.

Discharging: The crushed material is discharged through the discharge port. The size and shape of the discharge particle size can be adjusted by replacing screens or grate plates of different specifications. Multiple discharge ports can be set as needed to achieve multi-stage crushing and screening.

Circulation: Some materials that do not meet the requirements can be re-entered into the crushing chamber through the return device for re-crushing. This ensures that all materials can achieve the expected crushing effect, improve crushing efficiency and product quality.

Advantages

High efficiency and energy saving: The cage crusher uses a high-speed rotating cage rotor to impact and shear the material, with high crushing efficiency and low energy consumption. Compared with traditional crushing equipment, the cage crusher can crush materials into the required particle size more quickly while consuming less energy.

Strong adaptability: The cage crusher can handle materials of various hardness and humidity, and has strong adaptability. Whether it is brittle or tough materials, whether it is dry or wet materials, the cage crusher can effectively perform crushing operations.

Uniform product particle size: Due to the special shape and arrangement of the cage bars and the multiple impacts and shearing actions in the crushing chamber, the particle size of the crushed product is uniform and easy to control. This helps to improve the quality and market competitiveness of the product.

Easy maintenance: The structure of the cage crusher is relatively simple and easy to maintain. Since the main components such as the cage rotor and the crushing chamber are made of wear-resistant materials, the equipment has less wear and a long service life. At the same time, the lubrication and maintenance of the equipment are relatively simple and convenient, which can reduce downtime and maintenance costs.

Excellent environmental performance: During the crushing process, the cage crusher produces less dust and lower noise, which meets environmental protection requirements. In addition, the equipment can be equipped with auxiliary equipment such as dust removal devices and sound insulation facilities to further improve environmental performance.

Easy operation: The operation of the cage crusher is relatively simple, intuitive and easy to master. Users only need to follow the instructions or operating procedures to complete the crushing operation. At the same time, the equipment is also equipped with a variety of safety protection devices such as overload protection and overheating protection to ensure the safety of operators and the stable operation of the equipment.

Customizable design: According to different needs and material characteristics, the cage crusher can be customized to meet specific crushing requirements. For example, the shape and arrangement of the cage bars can be adjusted, the shape and size of the crushing chamber can be changed, and the number of discharge ports can be increased or decreased. This flexibility enables the cage crusher to better adapt to the needs of different industries and fields.

In summary, cage crusher has become one of the important equipment in the crushing field due to its advantages such as high efficiency and energy saving, strong adaptability and uniform product particle size.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!