Guide to SOP Based Fertilizer: Costs, Challenges, and Best Practices with LANE Heavy Industry

Introduction: The Rising Star of Specialty Fertilizers

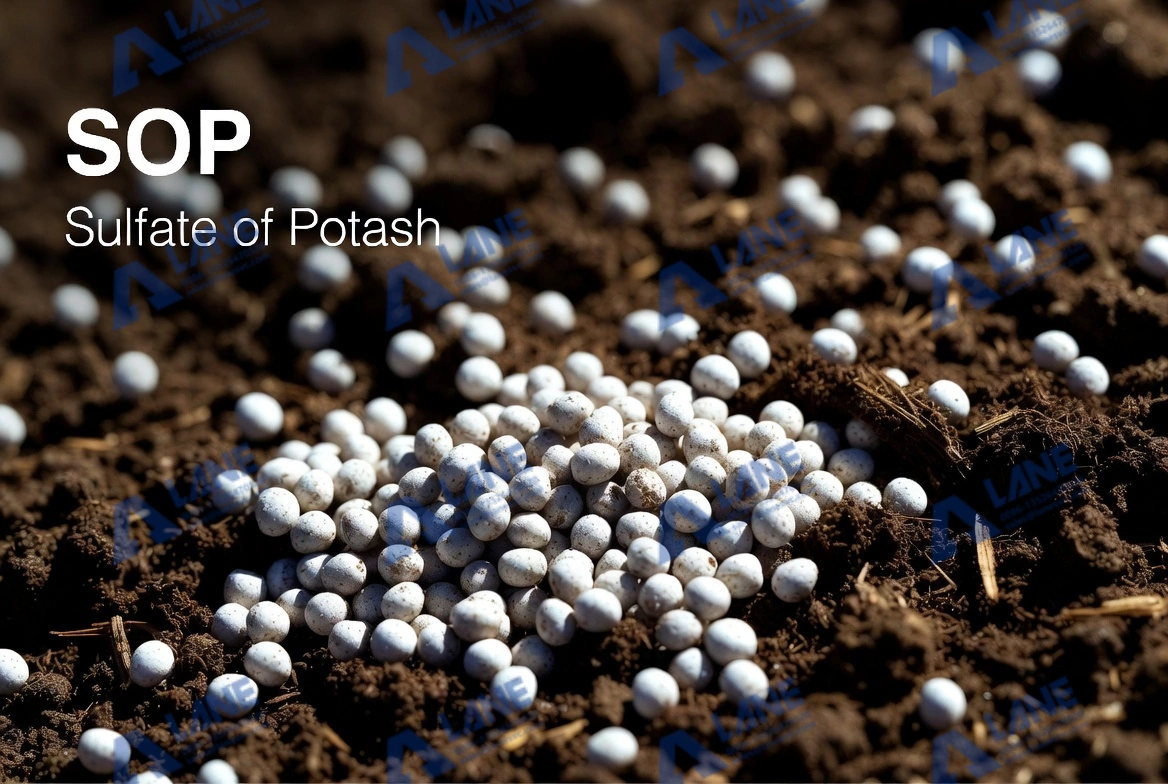

In the evolving landscape of the agriculture industry, Sulfate of Potash has gained significant attention due to its high efficiency and great performance for chloride-sensitive crops like fruits, vegetables, nuts, and tobacco. Unlike traditional potassium chloride (KCl) fertilizers, SOP contains no chloride. However, a successful production needs more than chemical knowledge; it requires an understanding of specialized processes, cost controls, and reliable machinery.

This guide will explore the critical aspects of establishing an SOP based fertilizer production line with the help of leading industrial fertilizer production line manufacturer LANE Heavy Industry.

What is SOP Based Fertilizer and Why Does Production Matter?

SOP (K₂SO₄) is a premium fertilizer which provides both potassium (K) and sulfur (S) in readily available sulfate forms. SOP contains no chloride, which makes it ideal for crops where chloride can affect yield, quality, and taste.

The final product’s quality—like its granule or crystal size, hardness, dust content, and solubility—directly impacts its handling, storage, and blending compatibility. A well-engineered production process creates consistent, high-value premium fertilizer that commands market preference and premium pricing.

The Core Production Process: From Raw Potash to Premium SOP

There are a few methods for SOP fertilizer production, like the Mannheim Process or conversion from MOP. But all SOP based fertilizer production lines involve key stages.

- Raw Material Preparation: The first step is getting high-purity raw material for SOP.

- Chemical Reaction Process: If the raw material is MOP, then it is refined using the Mannheim Process, where the chloride is separated by mixing sulfur. In this process, a high-quality by-product named hydrochloric acid can be created with proper planning.

- Crusher: The hard crystal from the furnace is crushed into a fine, consistent powder.

- Granulation/Agglomeration: The crushed fine powder is then sent to the Double Roller Granulator for dry granulation. In this process, two rollers press the powders to create stone. For large quantities, a rotary drum granulator is used.

- Drying: The granules are then sent to a drying machine to reduce the moisture to an optimal level to achieve necessary hardness and stability.

- Cooling: Hot granules are then cooled in a LANE rotary cooler to prevent caking during storage.

- Screening & Classification: Granules are then sent to a screening machine to screen out the dust and oversized granules. They are sent back to the crusher.

- Coating & Finishing: A LANE rotary coating machine is used to apply coating to reduce dust, enhance flow, or add micronutrients to the granules.

- Packaging & Storage: The final step of the production is packaging. After that, the finished SOP based fertilizer is bagged or stored in bulk.

Analyzing the Cost Structure of SOP Based Fertilizer Production

Understanding the cost of production will help you calculate your profitability. Major costs of an SOP based fertilizer production line include:

Raw Materials (40-60%): Raw materials are the largest cost driver of a production line. The raw materials include potassium sulfate powder or MOP for conversion and sulfuric acid for the Mannheim process.

Energy (15-25%): Thermal energy is required for drying and reactors. Electrical power is needed for motors, mills, and fans.

Labor & Maintenance (10-20%): You will need skilled operators and a maintenance crew.

Capital Depreciation & Financing: The initial investment in land, buildings, and, crucially, production machinery is amortized over the plant’s life.

Logistics & Packaging: You will also have to account for bags, pallets, and transportation.

Navigating Key Production Challenges

Producers face several consistent challenges:

Corrosion Control: SOP processes involving sulfates or acids are highly corrosive. Equipment must be made with corrosion-resistant materials.

Dust Management and Product Loss: Every fertilizer production line creates dust. Without dust management, you will face product loss, environmental issues, and safety hazards.

Granule Strength and Uniformity: Achieving consistent, hard granules without crumbling is a technical challenge that requires reliable machinery

Process Inefficiency and Downtime: Unplanned production line stoppages and bottlenecks will waste raw materials and cripple profitability.

Scalability: Design a production line that can be scaled to meet growing demand without a complete overhaul.

Best Practices for Efficient and Profitable SOP Manufacturing

Front-End Engineering Design (FEED):Invest in the design process. Define your product specifications, process flow diagrams, and equipment lists, or hire a manufacturer like LANE who does this as their turnkey solution.

Invest in Corrosion-Resistant Equipment:The equipment in the production line has to be corrosion-resistant (e.g., 316L stainless steel, specialized linings).

Implement Closed-Loop Systems: Choose a closed-loop system for dust and off-spec materials back into the process and for valuable by-product creation.

Adopt a Proactive Maintenance Culture: Create a maintenance schedule for critical equipment like granulators, dryers, and mills to prevent failure.

The LANE Heavy Industry Advantage: Engineering for Excellence

Partnership with an expert manufacturer like LANE, who provides a turnkey solution, will save you from the headache of the design phase. LANE Heavy Industry provides integrated machinery solutions engineered for the harsh, precise demands of fertilizer production, including SOP based fertilizer lines.

- Purpose-Built Rotary Units: LANE’s chemical processing units, granulation equipment, rotary dryers, and coolers are fabricated with the correct metallurgy, slope, internal lifter design, and corrosion-resistant materials that can handle SOP materials efficiently.

- Material Handling: From raw material feeders to bucket elevators and conveyor systems, LANE equipment is built for continuous, heavy-duty service with minimal spillage and dust generation.

- Integrated System Design: The greatest value of a LANE production line is its ability to supply a finished product which is consistent in its quality and nutrient value. All components of a LANE production line are engineered to work in harmony.

- Lifecycle Support: LANE provides installation supervision, operator training, and reliable after-sales service. This ensures the production line reaches and maintains its designed performance.

FAQ: Common Questions on SOP Based Fertilizer Production

Q1: What is the main difference between SOP and MOP-based fertilizers?

A:SOP (Sulfate of Potash, K₂SO₄) is chloride-free and supplies potassium in sulfate form, ideal for chloride-sensitive crops. MOP (Muriate of Potash, KCl) contains chloride and is generally cheaper but can harm certain crops and soil health over time.

Q2: What is the most significant cost in producing SOP based fertilizer?

A: Raw materials (the source of potassium and sulfur) typically represent 40-60% of the production cost, making sourcing and process yield efficiency critical.

Q3: Why is equipment corrosion such a big issue in SOP production?

A: The sulfate ion and any residual acids from processes like Mannheim are highly corrosive. Standard carbon steel equipment will degrade rapidly, leading to contamination, leaks, and frequent, costly replacements.

Q4: How can I improve the physical quality (hardness, shape) of my SOP granules?

A: Granule quality is controlled in the granulation and drying stages. Using a well-designed granulation drum with precise liquid binder spraying and a correctly sized rotary dryer with controlled temperature profiles are essential for forming hard, spherical granules.

Q5: Why should I consider an integrated machinery supplier like LANE Heavy Industry?

A: An integrated supplier ensures all components of your production line are compatible and optimized to work together. This reduces engineering risks, improves overall system efficiency, simplifies maintenance, and provides single-point accountability for the entire process.

Conclusion: Building a Future-Proof SOP Production Line

As the demand for chloride-free, high-efficiency fertilizers grows, SOP based production will become more popular. Venturing into SOP based fertilizer production is and will continue to be a rewarding opportunity. The right foundation in production technology is the key to unlocking the full potential of this premium fertilizer. By partnering with LANE Heavy Industry, you can deliver high-quality SOP fertilizers and gain a competitive edge in the evolving agricultural industry.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment