Building a Brand on Quality: How Mastery of the SOP fertilizer chemical formula Enhances Your Product Line

In the competitive fertilizer market, brand differentiation and quality of the product is the main source of customer accusation. Customers often choose products based on the price but if the quality of these products is not good then they will turn away. On the other hand, building a brand based specialized customizable high quality SOP fertilizer by mastering SOP fertilizer chemical formula will always intrigue the customers.

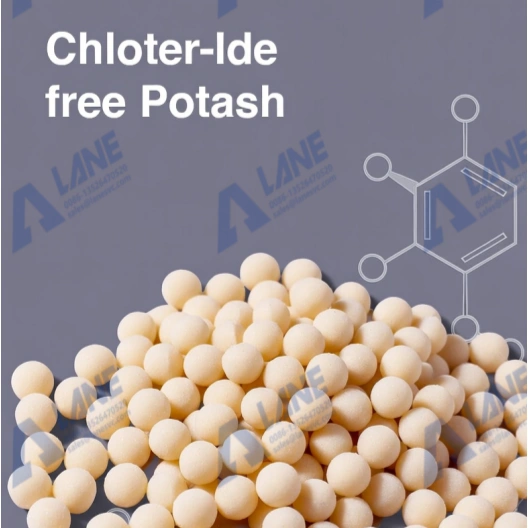

premium fertilizers like Sulfate of Potash (SOP), product quality is the most important factor in the fertilizer market. The secret of superior SOP product lies a deep mastery of the SOP fertilizer chemical formula, K₂SO₄. It dictates the ratio of potassium, sulfur, and other trace elements which directly affects the fertilizer’s effectiveness.

The Uncompromising Science: K₂SO₄ as Your Blueprint

The SOP fertilizer chemical formula refers to the scientific proportioning of raw materials to produce potassium sulfate fertilizer with specific nutrient content and physical properties. The basic SOP fertilizer chemical formula is K₂SO₄, with a potassium oxide (K₂O) content of 54.06% and sulfur (S) content of 18.40%. But in actual production, the SOP fertilizer chemical formula needs to be adjusted according to factors such as target crops, soil conditions, and regional needs. For example, fertilizer for fruit trees requires a higher potassium content for fruit swelling and sugar accumulation, while fertilizer for leafy vegetables needs a balanced ratio of potassium and sulfur to enhance leaf growth.

A premium SOP fertilizer chemical formula needs to meet two requirements: nutritional effectiveness and stability. The mastery of the formula begins with the sourcing and processing of the raw materials. The producer has to master the natural brines or the Mannheim process to achieve a high-purity K₂SO₄ crystal. There cannot be any impurity remaining in the raw materials. Therefore, control over the chemical formula is the non-negotiable first step.

From Formula to Physical Form: The Engineering Challenge

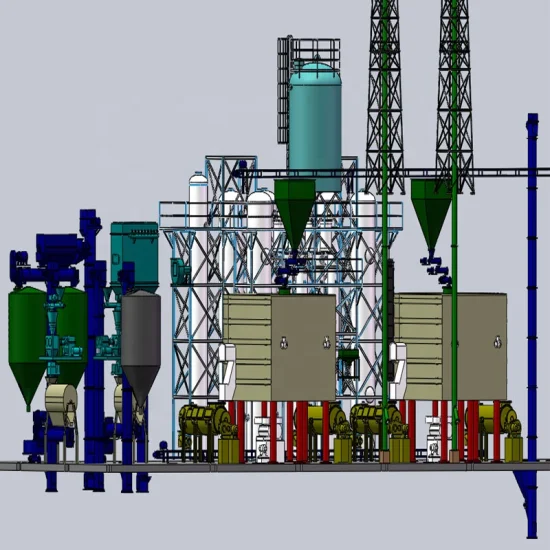

A chemical formula means nothing without the means to deliver it perfectly. The formula must be realized into a consistent, durable, and user-friendly physical form. This is the core challenge of the SOP fertilizer production line. A production line has several critical stages:

Granulation: In this stage, raw SOP fine powder is transformed into strong, dust-free granules.

Drying: Drying removes the extra moisture without degrading the heat-sensitive K₂SO₄.

Cooling: After drying, it is essential to cool the granules to ambient temperature for handling and storage.

Screening: This process separates on-size granules from the fines and oversized granules and sends them to crushers to be recycled back into production.

Coating: Applying anti-caking agents to ensure flowability.

Each of these stages must be uniform and able to maintain the integrity of the SOP fertilizer chemical formula. For example, inefficient drying can lead to caking, or poor granulation can result in dust particles or weak granules that break down in transit.

Precision in Production: Where LANE Heavy Industry Machinery Excels

LANE Heavy Industry provides durable, precise machinery that keeps the purity of your K₂SO₄ formula and creates the perfect final product.

Granulation Excellence: LANE Heavy Industry provides rotary drum granulation for large-scale production lines and, for small and medium-scale production lines, we engineer double roller compact granulators. They are engineered for uniform granule formation.

LANE’s rotary drum granulators and state-of-the-art compact pellet mills are engineered for high yield and uniform granule formation. Their designs ensure an even distribution of binding agents (if used) and create dense, spherical granules that are highly resistant to attrition, preserving your valuable K₂SO₄ from dust loss.

Drying and Cooling Processing: LANE understands that excessive heat can affect product quality. LANE’s concurrent-flow rotary dryers and coolers are designed for optimal heat transfer and gentle product handling. Users can control the heat and air of the machines to maintain the chemical integrity of the SOP fertilizer chemical formula.

Integrated System Reliability: LANE Heavy Industry designs production lines as collective systems. From feeding and mixing to final screening and coating, the production line is designed to work with each other at every step of the process. The fully automated system with PLC control ensures consistent, uninterrupted output, guaranteeing that every bag that leaves your plant meets the same high standard. By leveraging our machinery, you take complete control over the physical attributes of your production line.

The Quality Cascade: How Chemical and Mechanical Mastery Builds Your Brand

The synergy of chemical and mechanical precision creates a powerful “quality cascade” that builds your brand at every touchpoint:

For the Farmer (End-User): They experience a reliable, easy-to-apply product that delivers predictable, superior crop results. SOP fertilizer is the premium option for high-value, chloride-sensitive crops. This builds loyalty to your brand.

For the Distributor: They receive a product that is free-flowing, dust-free, and uniform and easily sellable. The reduced handling stress and logistical headaches make your brand synonymous with reliability in the supply chain.

For Your Marketing Team: Quality becomes the best advertising for a product. Your high-purity, precision-granulated K₂SO₄, along with a superior production line, gives you the perfect marketing materials to prove your commitment.

For Your Business: LANE’s production line takes your SOP fertilizer chemical formula and creates a product that is superior and enhances your operational efficiency. It builds doors to new, demanding markets and provides resilience against competitors who compete on price alone.

Conclusion: Investing in the Foundation of Trust

In the long-term endeavor of brand building, the SOP fertilizer chemical formula (K₂SO₄) is your scientific truth. By integrating the mastery of the SOP fertilizer chemical formula with LANE Heavy Industry’s machinery, fertilizer manufacturers can enhance their product lines, meet the diverse needs of customers, and build long-term customer trust.

A brand built on this foundation of quality does not just sell fertilizer; it sells confidence, yield potential, and a partnership in the grower’s success. It transforms your product line from a commodity into a benchmark for excellence in the agricultural industry.

Frequently Asked Questions (FAQ)

Q1: Why is the SOP fertilizer chemical formula (K₂SO₄) considered premium?

A1: K₂SO₄ provides potassium in a sulfate form, which is immediately available to plants and contains no chloride. This makes it ideal for improving quality, yield, and disease resistance in chloride-sensitive high-value crops, justifying its premium status over muriate of potash (KCl).

Q2: How does machinery affect the quality of SOP beyond its chemical formula?

A2: Even with 100% pure K₂SO₄, poor machinery can produce dusty, weak, or irregularly sized granules. This leads to caking, poor spreadability, and nutrient segregation. Precision machinery ensures the chemical purity is preserved in a physically superior product that is easy to handle, store, and apply.

Q3: What makes LANE Heavy Industry’s equipment suitable for premium SOP production?

A3: LANE designs equipment for precision and durability. Their granulators create strong, uniform granules; their dryers and coolers gently process heat-sensitive K₂SO₄; and their integrated systems ensure consistent, high-volume output with minimal downtime—all critical for maintaining the stringent quality standards of a premium brand.

Q4: Can the same production line handle different fertilizer grades?

A4: While dedicated lines are ideal for purity, modern lines from providers like LANE Heavy Industry can be designed with flexibility in mind, allowing for production of various SOP-based blends or granule sizes. However, rigorous cleaning protocols are essential to prevent cross-contamination when switching between products.

Q5: Is investing in high-end production equipment worth the cost for an SOP brand?

A5: Absolutely. The return on investment comes through superior product consistency, reduced waste and reprocessing costs, the ability to command a higher market price, and the incalculable value of a strong, trusted brand reputation that drives customer loyalty and market share growth.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment