Optimizing SOP Fertilizer Composition in a Modern Production Line

Introduction: The Critical Link Between Process and Product

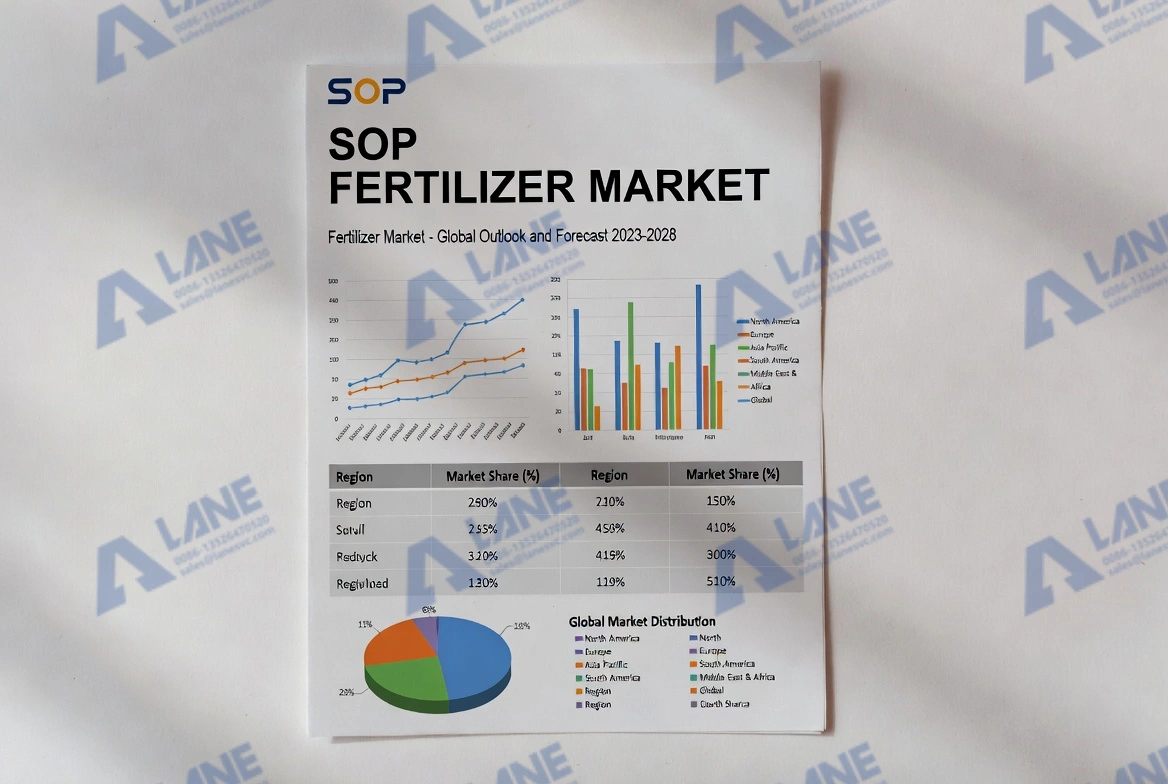

By 2050, the world will have 9.5 billion people. To feed that many people, the agriculture industry has to grow by 60%. This will require modern technology and lots of fertilizers. This is an opportunity for agribusiness and investors. The demand for fertilizer will increase along with food production. They are facing pressure to improve product quality and production efficiency. Sulfate of Potash (SOP) is a premium potash fertilizer which is widely used for cash crops like coffee, fruits, and vegetables. Its marketability directly depends on two factors: SOP fertilizer composition and its granule strength and low dust.

The optimization of SOP fertilizer composition is a core focus for manufacturers to gain profit. LANE Heavy Industry, a leader in the fertilizer equipment industry, provides advanced modern production lines for SOP fertilizer.

Understanding SOP Fertilizer Composition

The standard formula for SOP fertilizer is (K₂SO₄). Modern commercial SOP fertilizer formula is carefully balanced. It involves:

- Primary Nutrient Concentration: A high-quality SOP fertilizer must have a minimum of 50% potassium as K₂O and 18% sulfur as S. Consistency in this formulation is what gains the trust from the market.

- Chloride (Cl) Content: The key selling point of SOP is its low chloride content (<1.5-2.5%). This is critical for chloride-sensitive crops. The production process of SOP must actively minimize chloride contamination.

- Micronutrients and Additives: Some premium SOP fertilizer blends include magnesium, boron, or other micronutrients. This requires a mixing machine for homogenous mixing.

- Physical Specifications: Granule size (e.g., 2-4 mm), crushing strength, and moisture content are integral to the final product’s “composition” as they affect storage, handling, and soil release.

To handle this optimization, you will need a production line that is designed for precision, flexibility, and control.

The LANE Production Line: A System for Precision

The SOP production line from LANE Heavy Industry is a synchronized system that is designed to work with each other. Each unit contributes directly to the final SOP fertilizer composition.

3.1 Raw Material Handling and Precision Batching

The foundation of consistent composition starts from the very beginning. LANE’s automated Dynamic Batching system receives and weighs raw materials (for Mannheim-process intermediates like potassium chloride and sulfuric acid or sulfate salts like langbeinite). This ensures exact recipe formulation. The precision feeding system feeds the raw material in correct ratios to the furnace. This is the first and most critical step for SOP fertilizer composition.

3.2 The Granulation Heart: Achieving Perfect Physical Form

After the chemical process, SOP fertilizer cake needs to be crushed to make fine powder. Then it is sent to the main granulation line. This is where it takes granule shape. Before granulation, you can use a mixer to create premium SOP fertilizer composition by adding micronutrients. LANE’s advanced rotary drum granulators provide the ideal environment for agglomeration.

- Spray Systems: LANE Rotary Granulator contains a spray system that injects binders to ensure optimal granule size.

- Control Parameters: You can tune drum speed, angle, and retention time. This allows the operator to create the desired granule size distribution and density. This directly influences nutrient release patterns.

3.3 Drying & Cooling: Preserving Nutrient Integrity

LANE’s rotary dryers apply gentle, concurrent-flow heat to remove moisture from the granules without causing any harm. Too much heat can cause degradation or thermal shock to granules, which leads to crumbling and dust. Subsequently, the rotary cooler stabilizes the product, preventing caking during storage and locking in the granule integrity that protects the precise SOP fertilizer composition inside.

3.4 Screening and Coating: The Final Touches for Quality

- Rotary Screening: In this process, oversized and undersized granules are separated from the on-size granules and sent to the crusher to be recycled back to the granulator. This ensures raw material efficiency and consistency.

- Coating Drum: A final coating of anti-caking agents is applied in this stage with the help of the LANE coating drum. This ensures flowability, reduces dust, and provides a final protective layer. It increases the shelf life of the SOP fertilizer.

Key Benefits of an Optimized, Integrated Line

An experienced manufacturer like LANE Heavy Industry delivers a modern, fully integrated line that has:

- Unmatched Compositional Consistency:Every batch has the same composition in the LANE production line. You can clone your product formula so the K₂O, S, and Cl content in the production remains the same.

- Enhanced Product Value:A strong granule along with uniform size and low dust has high market value and commands premium prices in the market.

- Operational Efficiency:Closed-loop recycling of fines and oversized granules reduces raw material waste and energy consumption.

- Formula Flexibility:The line can be adapted to produce SOP blends with added micronutrients. This allows manufacturers to respond to market trends.

Conclusion: Investing in Compositional Excellence

Optimizing SOP fertilizer composition is the key to improving the quality of SOP fertilizer and promoting agricultural development. In the market, SOP fertilizer composition is the ultimate determinant of quality and efficacy. Optimizing this is an engineering challenge. LANE Heavy Industry’s modern production lines, with their advantages of high efficiency, intelligence, and customization, provide reliable equipment support for the optimization of SOP fertilizer composition.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between SOP and MOP fertilizer composition?

A1: The core difference is the anion paired with potassium. SOP (Sulfate of Potash) provides K₂O and sulfate sulfur (S) with very low chloride (<2.5%). MOP (Muriate of Potash, KCl) provides potassium but with a high chloride content (typically 47% Cl). This makes SOP essential for chloride-sensitive crops like tobacco, fruits, and vegetables.

Q2: How does LANE’s production line specifically improve the consistency of SOP fertilizer composition?

A2: LANE’s line employs automated, precision batching systems for raw materials, ensuring exact recipe input. Furthermore, the controlled granulation and uniform drying/cooling processes create homogeneous granules where the nutrient composition is identical from the core to the surface and consistent across every batch.

Q3: Can the same LANE production line produce different grades of SOP?

A3: Yes, a well-designed LANE line offers significant flexibility. By adjusting the raw material feed formula and utilizing precise additive injection systems in the granulator, the same line can produce standard 0-0-50 SOP, enriched SOP with magnesium, or other custom blends to meet specific market demands.

Q4: Why is the cooling stage important for final SOP product quality?

A4: Proper cooling stabilizes the granules after drying, preventing them from sticking together (caking) during storage and transportation. This preserves the physical integrity of the granule, which in turn protects the precise SOP fertilizer composition inside and ensures the product remains free-flowing for the end-user.

Q5: What is the role of the coating drum in the SOP production process?

A5: The coating drum applies a thin, uniform layer of anti-caking or dust suppression agent. This is the final step in quality assurance, enhancing the product’s shelf life, handling characteristics, and overall appearance, which are critical for a premium product like SOP.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment