Solving Sodium Contamination: Designing an Effective Low Sodium SOP Fertilizer Production Line

Introduction: The Imperative for Low Sodium SOP

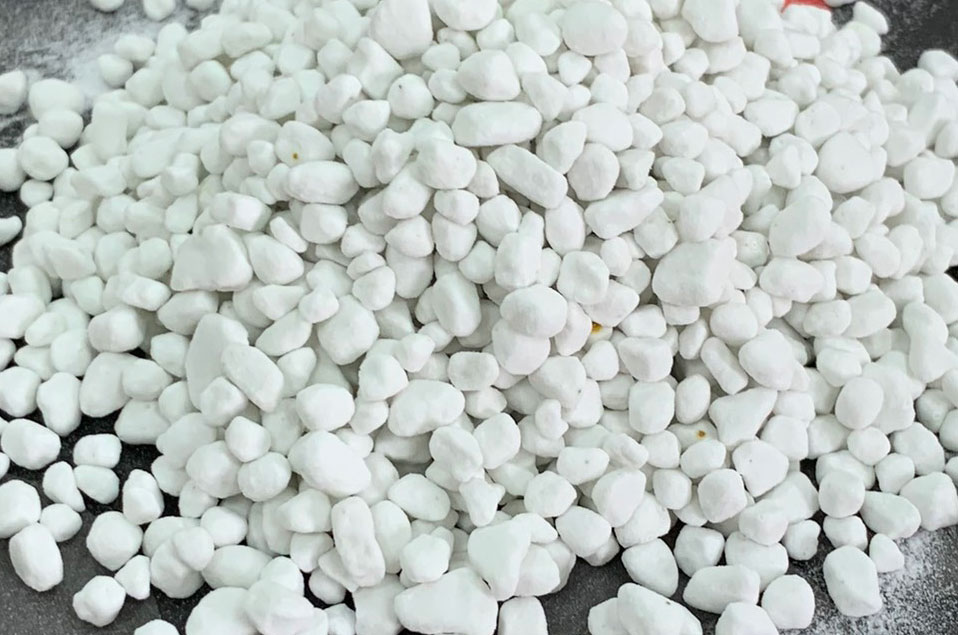

Sulfate of Potash (SOP) is highly valued for its chloride-free, potassium-rich profile. It is very popular for chloride-sensitive crops such as tobacco, fruits, and vegetables. It provides up to 18% sulfur with up to 52% potassium. But not all SOP fertilizer is created equal. Sodium chloride (NaCl) contamination in the production process has become a problem that restricts production quality. Sodium chloride (NaCl) and other sodium compounds undermine the benefit of SOP, which leads to soil salinization, reduced crop quality, and yield loss.

Sodium inhibits crop root growth and seed germination along with soil quality loss. This leads farmers to look for high-quality low sodium SOP fertilizer. It has become the mainstream direction of the industry. The demand for low sodium SOP fertilizer is rapidly growing among growers and premium fertilizer blenders. Meeting this demand requires a fundamentally sound production line that can perform precision tasks and safety measures. At LANE Heavy Industry, we specialize in engineering turnkey solutions that transform raw materials into consistent, high-purity, low sodium SOP fertilizer.

The Sodium Contamination Challenge in SOP Production

Sodium contamination occurs from the raw materials used in SOP production methods such as the Mannheim process (using potassium chloride and sulfuric acid) or sulfate-based double decomposition reactions (using KCl and various sulfate sources like langbeinite or sodium sulfate).

The core challenge of low sodium SOP fertilizer is both chemical and physical. The sodium ions are highly soluble and can be trapped within potassium sulfate crystals during crystallization. Poor washing quality, inefficient crystallization control, or low-quality raw materials can lock sodium impurities into the final product. A normal SOP fertilizer production line doesn’t have measures to control these. A production line created by LANE has stages that target these specific problems to isolate and remove these contaminants.

Core Principles of a Low-Sodium SOP Production Line

A low sodium SOP fertilizer production line must maintain some core engineering principles to have premium quality fertilizer.

- Pre-Emptive Purification: The first principle is to address the raw material selection problem and sort them properly with advanced raw material conditioning and preparation.

- Precision Crystallization: Controlling the crystallization to favor the growth of pure K₂SO₄ crystals while removing sodium ions from the crystal.

- Mechanical & Chemical Washing: Implementing a multi-stage counter-current washing system that uses saturated SOP solution or purified water to dissolve and flush away surface sodium salts without dissolving the product.

The LANE Heavy Industry Solution: A 4-Stage Process

Our production lines are engineered as integrated systems, where each stage is optimized for purity.

| Stage | Process | Role in Reducing Sodium |

| 1. Feedstock Prep & Reaction | Controlled feeding and reaction in specialized reactors (e.g., Mannheim or Glaser). | Ensures stoichiometric balance to minimize residual reactants that lead to by-products. |

| 2. Primary Crystallization | Forced-circulation vacuum crystallizers with precise control over supersaturation. | Promotes the growth of large, regular K₂SO₄ crystals; sodium remains in the liquor. |

| 3. Solid-Liquid Separation | High-efficiency centrifuges with cake washing features. | Physically separates crystals from sodium-rich mother liquor; first-stage wash applied here. |

| 4. Refined Washing & Drying | Counter-current washing classifiers and indirect dryers. | Final, intensive wash with pure solution; low-heat drying to prevent salt caking and impurity entrapment. |

Stage 1: Intelligent Reaction Engineering

Our reactors are designed for precise temperature and pressure controls. they ensure complete reaction which minimizes unreacted salts. For certain raw material, we integrate pre-washing systems to reduce initial sodium load.

Stage 2: The Heart of Purity: Precision Crystallization

This is the most critical stage. Our forced-circulation crystallizers allow us to control cooling rates and density. By carefully managing supersaturation, we produce well-formed coarse SOP crystals. These larger crustal has lower surface area to volume ratio and trap less sodium rich mother liquor within their structure. This makes subsequent washing more effective.

Stage 3 & 4: The Purification Cascade

Our Low sodium SOP fertilizer production line utilizes liquid removal and cleansing at the same time. Our centrifuges are equipped with spray nozzles that apply a saturated SOP solution during spin-up, displacing impure mother liquor. The crystals then moved to a multi-stage washing classifier where they are gently agitated in a counter-current flow of clean, saturated SOP solution. This dissolves the surface sodium without dissolving the potassium sulfate. Finally, a low- temperature dryer ensures the products physical stability without re-introducing impurities.

Advanced Control & Quality Assurance

A mechanical line needs a good control system to be more efficient than normal production line. Our PLC based automation integrates:

- Online Conductivity & Density Meters: To monitor mother liquor purity in real-time.

- Automated Wash Water Control: To optimize flow rates and concentration for maximum sodium removal with minimal product loss.

- Integrated Sampling Systems: For automated lab analysis, ensuring the final product consistently meets the low sodium SOP fertilizer specification (often <0.3% Na).

Our Data-driven approach allows for closed loop adjustments. This guarantees batch to batch consistency which provides full traceability.

Conclusion: Investing in Precision for Premium Output

Solving sodium contamination in SOP fertilizer production is a requirement for the high-quality development of high-efficiency agriculture. Producing low sodium SOP fertilizer is a clear response to market demand for sustainable solution. LANE Heavy Industry, a leader in fertilizer production machinery and turnkey solution, delivers a guaranteed process. From raw material intake to bagged premium product, our engineered solutions are designed to systematically solve the problem of sodium contamination. Investing in such a line is an investment in product differentiation, brand reputation, and alignment with the future of precision agriculture.

Frequently Asked Questions (FAQ)

Q1: What is considered “low sodium” in SOP fertilizer?

A: While specifications can vary, premium low sodium SOP fertilizer typically contains less than 0.3% sodium (Na) by weight, and often as low as 0.1%. This is a significant reduction compared to standard SOP, which can contain 0.5% Na or higher.

Q2: Can I convert my existing standard SOP line to produce low sodium SOP?

A: It is possible, but requires significant retrofitting. Key upgrades usually include adding or modifying crystallization controls, installing high-wash centrifuges, integrating a counter-current washing system, and implementing advanced process control. LANE Heavy Industry offers feasibility studies and retrofit packages to achieve this.

Q3: Does producing low sodium SOP significantly increase production costs?

A: There is an increase in operational cost due to the energy for precise crystallization, the management of wash liquors, and potentially higher-grade raw materials. However, this is offset by the significantly higher market price for premium low sodium SOP fertilizer and access to more lucrative market segments, leading to a stronger overall ROI.

Q4: How does LANE ensure the consistency of the final product’s sodium content?

A: We build consistency through “Quality by Design.” Our lines use automated process controls (PLC/DCS) that continuously monitor critical parameters. Online analyzers and automated sampling provide real-time data, allowing the system to auto-adjust wash rates, crystallization temperatures, and feed flows to maintain the product within the strict low-sodium specification.

Q5: What raw material is best for producing low sodium SOP?

A: The choice (e.g., potassium chloride with sulfuric acid vs. double decomposition routes) depends on local availability and economics. A key advantage of the LANE design is its flexibility and robustness. We engineer the purification stages to be effective across different feedstocks, ensuring a consistently low-sodium final product regardless of the chosen production method.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment