From Raw Materials to Premium Granules: How a 0-0-52 SOP Fertilizer Production Line Works

Introduction: The Premium Potassium Standard

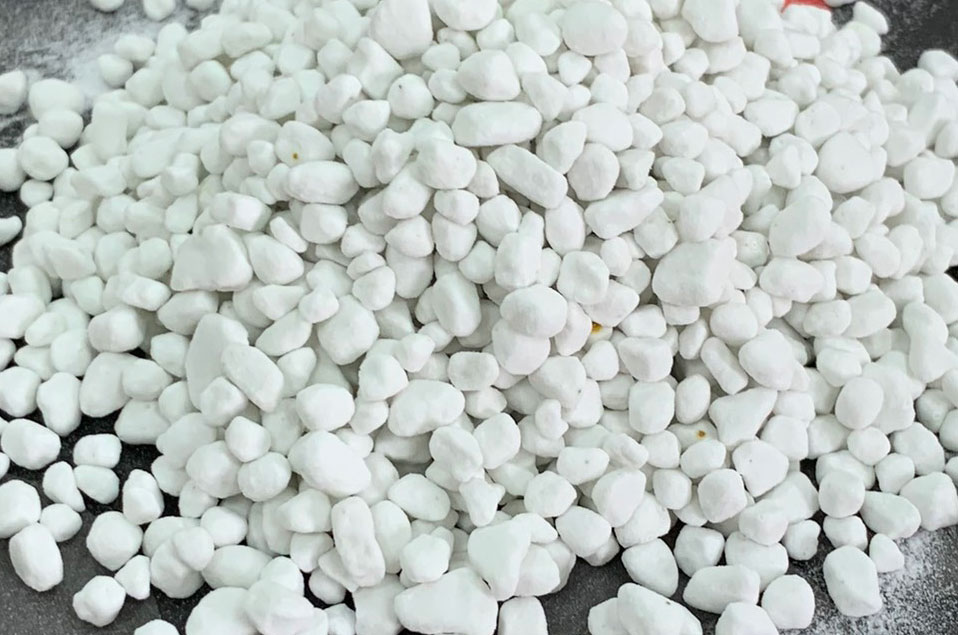

Premium Sulfate of Potash, or 0-0-52 SOP, is very popular for high-quality chloride-sensitive cash crops like fruits, vegetables, tobacco, and nuts. 0-0-52 SOP is a high-concentration potassium fertilizer with 52% potassium content. It helps crops with lodging resistance, improving fruit quality, and enhancing stress tolerance. It provides essential K₂O without any chloride while also supplying sulfate sulfur.

To produce this fertilizer, you will need more than just chemistry. It will require a specialized, precision-engineered 0-0-52 SOP fertilizer production line which can deliver a consistent high-quality final product. LANE Heavy Industry has designed and manufactured a dedicated 0-0-52 SOP fertilizer production line that integrates automation, precision control, and environmental protection.

The Foundation: Raw Materials for 0-0-52 SOP

The primary raw material for a standard 0-0-52 SOP production line is potassium sulfate (K₂SO₄). It can be sourced from:

- Naturally occurring ore like arcanite, which is very rare.

- The chemical reaction of potassium chloride and sulfuric acid.

- Refining Kainite and Schönite salts.

- Byproduct of Nitric Acid Production and Lithium Extraction.

The material arrives as a fine powder or crystalline substance. The secondary raw material is a binding agent like liquid water, which is crucial for the wet granulation process. The quality of the raw K₂SO₄ directly impacts the efficiency and final product’s purity.

The Production Line Process: A Step-by-Step Journey

LANE Heavy Industry’s integrated production line is a symphony of coordinated machinery. Here’s how raw materials become premium granules:

Stage 1: Crushing & Preparation

If the raw potassium sulfate is in large crystalline or lump form, it is first sent to the crusher. A LANE chain mill or cage crusher is used in this stage to achieve a consistent, fine powder.

Stage 2: Precise Mixing & Batching

The crushed powder is conveyed to a LANE mixer. Here, the operator can mix SOP with their custom formulation. LANE’s advanced mixing technology ensures homogeneous mixing ready for agglomeration.

Stage 3: Granulation – The Heart of the Line

This is the core of the production line. The mixed raw materials are fed into the granulator in this stage. LANE typically uses:

- Rotary Drum Granulator: A large, rotating drum where the tumbling motion causes the fine particles to adhere and grow into spherical granules.

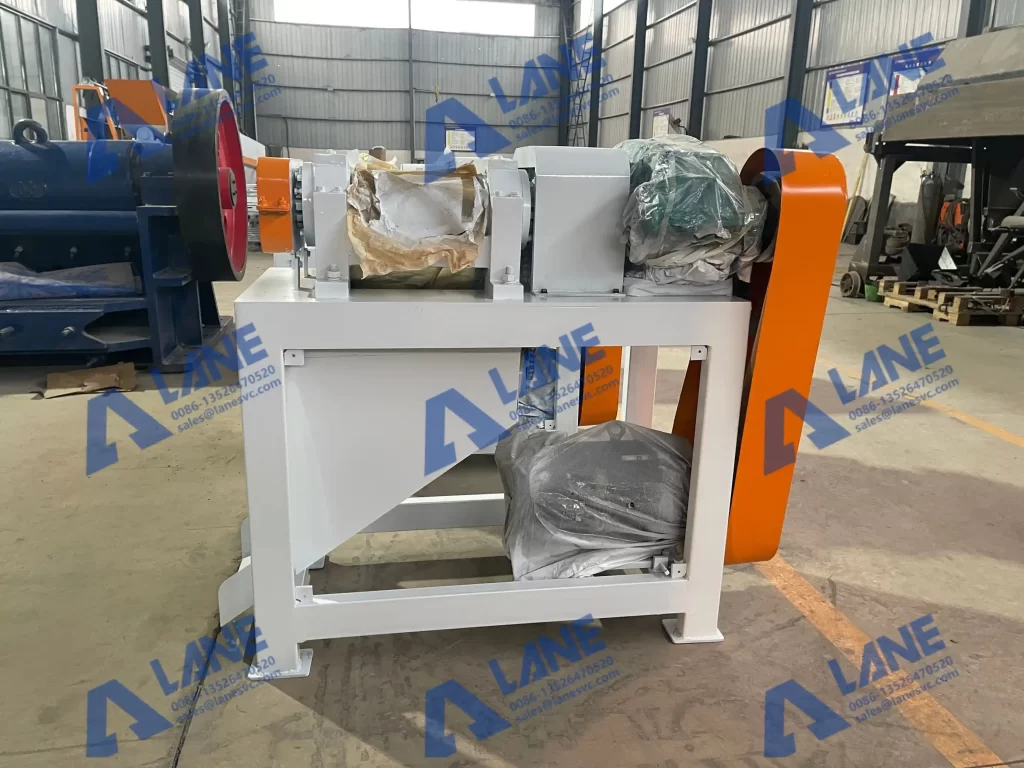

- Double-Roller Extrusion Granulator: This is a compact granulator. It creates high-density compact granules. This machine compresses the dry SOP powder into granules. It employs two counter-rotating rollers to press the dry powder into granule shape.

The choice of granulation method depends on desired size, density, and production capacity.

The granules from the granulator are soft and contain high moisture. They need to be dried. The granules are directly transferred into a rotary dryer, where hot air (from a hot air furnace) reduces moisture to a stable, durable level (<1.5%). Immediately after, the hot granules are sent to the rotary cooler to bring them closer to ambient temperature. This prepares them for the screening machine.

Stage 5: Screening & Recycling

After granulation, the granules vary in size. A rotary screening machine is used in this stage to separate them.

- On-spec granules (e.g., 2-4mm) are sent to coating.

- Oversized and undersized granules are crushed and recycled back to the mixer.

This closed-loop system ensures zero waste and 100% raw material utilization.

Stage 6: Coating & Polishing

In this stage, the on-spec granules are sent to a coating drum. A thin film of anti-caking or dust-suppression agent is applied to the granules. This step ensures the 0-0-52 SOP fertilizer remains free-flowing, dust-free, and non-caking during long-term storage and bulk handling.

Process Flow Summary Table

| Stage | Key Equipment | Function | Output |

| Preparation | Crusher, Feeder | Size reduction & metering | Uniform powder |

| Mixing | Horizontal Mixer | Blend powder with binder | Homogeneous damp mass |

| Granulation | Drum or Extrusion Granulator | Form particles into granules | wet granules |

| Thermal | Rotary Dryer & Cooler | Remove moisture, stabilize granules | Hardened, cool granules |

| Sizing | Rotary Screen | Separate granules by size | On-spec, oversize, undersize granules |

| Finishing | Coating Drum | Apply anti-cake/dust agent | Premium 0-0-52 SOP |

Why Choose a Dedicated SOP Production Line?

Investing in a specialized SOP production line from LANE offers many advantages:

- Purity Assurance: It minimizes cross-contamination risk, which is crucial for chloride-sensitive SOP markets.

- Process Optimization: Equipment and parameters are specially made for K₂SO₄’s specific physical properties.

- Higher Efficiency: Our dedicated production line utilizes a recycling loop and our granulator produces higher density granules. This reduces energy per ton.

- Product Quality: Our granulator produces hard, spherical granules with excellent crushing strength. The granules are consistent in nutrient distribution.

FAQ: Common Questions About 0-0-52 SOP Production

Q1: Can the same line produce other fertilizers like MOP or NPK?

A1: While possible with extensive cleaning and process adjustment, it is not recommended. Dedicated lines for 0-0-52 SOP prevent chloride contamination and are optimized for specific material behavior, ensuring peak efficiency and product integrity.

Q2: What is the production capacity range for such a line?

A2: LANE Heavy Industry designs modular lines with capacities typically ranging from 10,000 to 200,000 tons per year. The scale is customized based on raw material availability and market needs.

Q3: How important is the coating stage?

A3: Critical. Potassium sulfate can be slightly hygroscopic. A quality coating prevents moisture absorption, eliminates dust, and ensures the fertilizer remains in perfect, free-flowing condition from production until field application, preserving its premium value.

Q4: What are the key advantages of using a rotary drum granulator for SOP?

A4: It produces strong, spherical granules with excellent physical properties ideal for bulk blending and mechanical spreading. The tumbling action creates dense, dust-free granules that are highly resistant to breakdown during handling.

Conclusion: Investing in Quality with LANE Machinery

The journey from raw potassium sulfate to premium 0-0-52 SOP granules requires a precisely engineered production line that can produce premium quality granules. LANE Heavy Industry’s 0-0-52 SOP fertilizer production line realizes that goal through a scientific and rigorous workflow. We provide a complete solution that makes your work process very simple and automated. Our engineers provide installation services and after-sales service to make sure your production line keeps functioning even after 10 years of service. By controlling every step of the process with our production line, from granulation to coating, producers can guarantee a consistent, high-quality product that meets the exacting standards of modern, high-value agriculture.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment