Engineered Efficiency: The SOP Fertilizer from Mineral Production Line

Introduction: The Demand for Premium SOP

Modern agriculture demands high-quality crops along with high yield. This became the trend because of the demand for high-quality crops and increased population growth. SOP fertilizer is very popular among growers of high-quality cash crops for its dual nutrient value and low chloride content. This gives rise to demand for efficient SOP fertilizer from minerals.

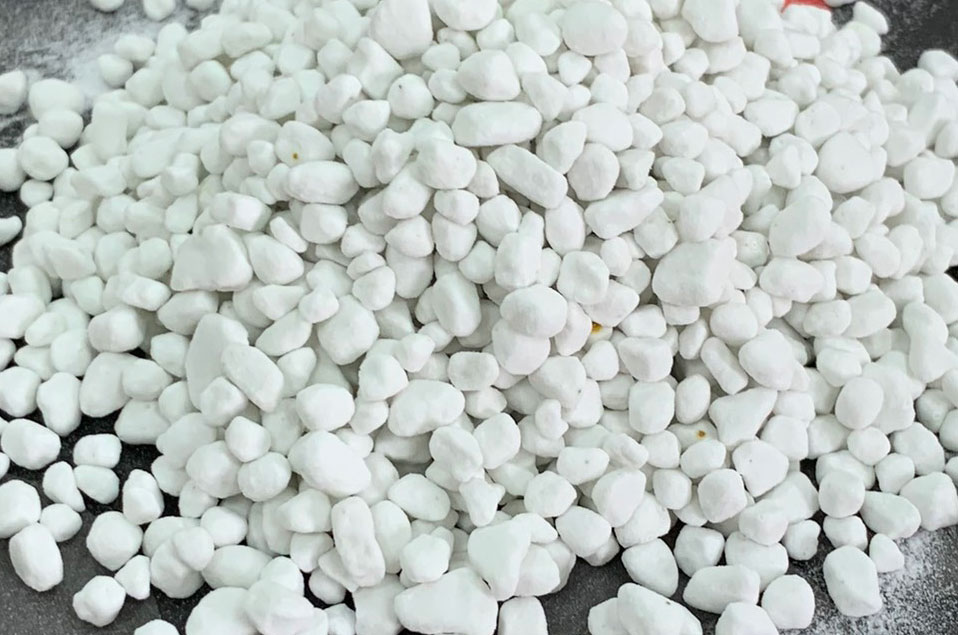

SOP (Potassium Sulfate) fertilizer is a high-concentration dual nutrient fertilizer that contains both potassium (K2O, up to 52%) and sulfur (S, up to 18%). It has become the preferred choice for growing pollution-free fruits, vegetables, and cash crops due to its excellent water solubility and non-toxicity. Among the various SOP production methods, the mineral-based production process stands out for its reliability, resource sustainability, and product purity. LANE Heavy Industry, a leader in heavy fertilizer machinery manufacturing, has designed an SOP fertilizer from mineral production line that transforms complex mineral ores into market-ready SOP.

From Core Minerals to Finished Product

The SOP Fertilizer from Mineral production line involves the processing of potassium-magnesium sulfate salts, most notably Langbeinite (K₂SO₄·2MgSO₄). This SOP Fertilizer from Mineral production line executes a series of physical and chemical operations like size reduction, dissolution via water, purification through crystallization, solid-liquid separation, thermal drying, and final granulation.

Each step demands machinery that has corrosion resistance, thermal exchange, precision control, and material throughput. An inefficient SOP fertilizer from mineral production line leads to bottlenecks, yield loss, and inconsistent product quality. An integrated production line from LANE Heavy Industry is the solution to these operational hurdles.

The LANE Heavy Industry Production Line: A Stage-by-Stage Breakdown

A modern SOP fertilizer from mineral production line is an interconnected, automated process. Here’s how a LANE-engineered line creates SOP fertilizer from minerals.

Stage 1: Raw Material Reception & Preparation

The process begins with the receipt and storage of raw langbeinite ore and purified water. LANE’s heavy-duty chain mill crusher reduces the mineral ore to a fine powder. This creates optimal surface area for the subsequent reaction stage. LANE’s automated conveyor systems ensure accurate, consistent raw material delivery to the reactor. This step is crucial in ensuring the quality and efficiency of the SOP Fertilizer from Mineral production line.

Stage 2: The Reaction & Conversion Circuit

This is the main process of the production line. Ground langbeinite is dissolved in water at an elevated temperature in a specially designed reactor vessel. LANE reactors are constructed from advanced corrosion-resistant alloys and feature optimized heat transfer surfaces to maintain exact thermal profiles, maximizing conversion yield. Proper control at this stage is essential for achieving the desired performance of the SOP Fertilizer from Mineral production line.

Stage 3: Crystallization & Purification

The dissolved solution now contains potassium sulfate and magnesium sulfate. It is cooled or evaporated under controlled conditions. Because potassium sulfate (K₂SO₄) has a lower solubility in water than magnesium sulfate (MgSO₄), it crystallizes out first. This stage is critical for determining the final product’s purity.

Stage 4: Solid-Liquid Separation

The SOP crystal slurry is then fed to high-capacity centrifuges. LANE’s industrial centrifuges provide high G-force separation, efficiently removing the mother liquor (which is rich in magnesium sulfate) and washing the crystals to achieve low chloride and magnesium content, meeting premium SOP specifications.

Stage 5: Crushing, Drying & Cooling

The wet cake is then conveyed to a Rotary Dryer, where it is contacted with hot air in a counter-current flow to reduce moisture to acceptable levels. This is then followed by a Rotary Cooler to stabilize the product temperature for handling and storage. The resulting cake is then sent to the crusher to create a fine powder for the granulation stage.

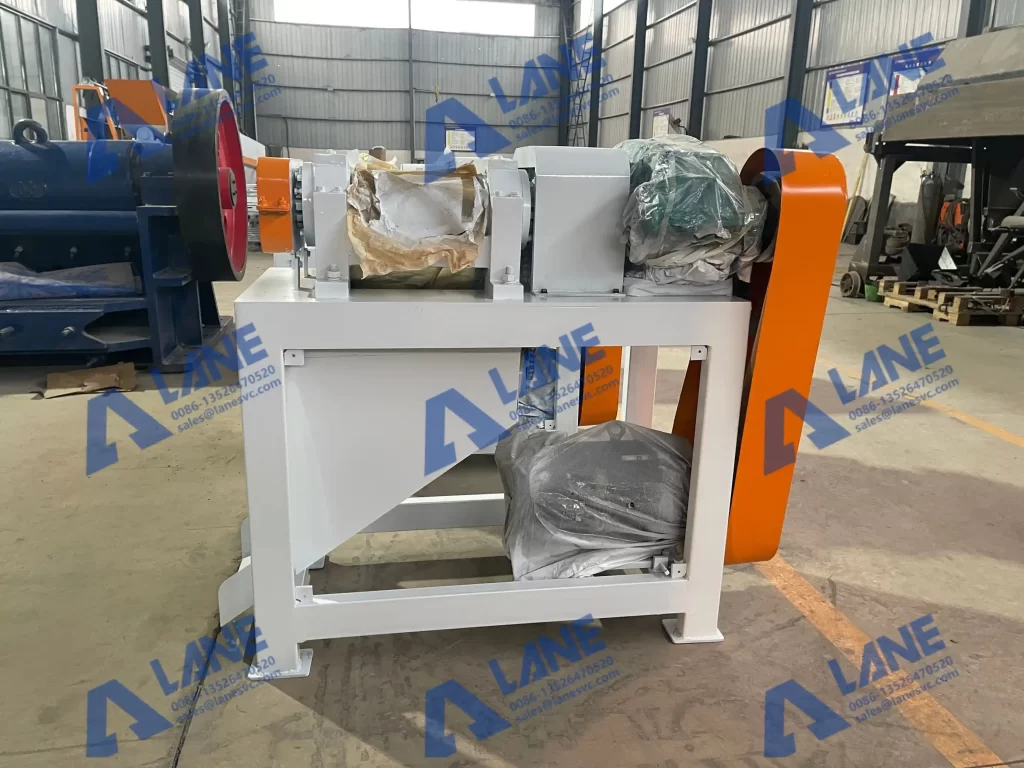

Stage 6: Granulation, Screening & Packaging

For a premium granular product, the dried SOP powder is sent to a LANE Double Roller Granulator. In this granulator, two counter-rotating rollers press and compact the powder to create granules. The finished SOP is conveyed to a screening machine to separate on-size granules from fines and oversized granules; off-spec material is sent back to the crusher to be recycled back into production. Finally, the finished SOP is conveyed to an automated bagging machine.

Key Machinery & Engineered Advantages

LANE Heavy Industry’s production line stands out due to its core machinery and engineered solutions.

- Corrosion-Resistant Reactor Systems: The machines are fabricated from 316SS and corrosion-resistant alloys to withstand aggressive chloride and sulfate environments.

- High-Yield Crystallizers: They are designed with precise control over evaporation rates and supersaturation to optimize crystal size and form.

- Unified Control System: We provide a centralized PLC/SCADA system that monitors and controls the entire line. It enables real-time optimization and rapid troubleshooting.

- Robust Material Handling: Every machine is built for 24/7 operation under harsh conditions.

Why Choose a LANE Integrated Line?

Choosing a complete SOP fertilizer from mineral production line from LANE Heavy Industry offers reliability and strategic advantages:

- Single-Point Responsibility: LANE takes accountability as the single supplier and eliminates interface compatibility issues.

- Optimized Process Flow: The production line is designed as a cohesive unit, ensuring balanced capacity across all stages to maximize throughput.

- Reduced Operational Risk: Proven designs and reliable machinery minimize downtime and maintenance costs.

- Scalability: Lines can be engineered from the outset for future capacity expansion.

Frequently Asked Questions (FAQ)

Q1: Can your production line use other mineral sources besides langbeinite?

A1: Yes. While optimized for langbeinite, the core reaction and purification principles can be adapted for other potassium-magnesium sulfate sources or for the Mannheim process with appropriate engineering modifications to handle different chemistries and inputs.

Q2: What is the typical capacity range for a LANE SOP production line?

A2: We engineer lines to meet specific client needs, with standard capacities ranging from 50 to 500 tons of finished SOP per day. Custom designs for larger capacities are also possible.

Q3: How do you ensure the final product meets granular quality (hardness, size) specifications?

A3: The combination of our controlled crystallization and granulation technology is key. We precisely manage parameters to produce hard, uniform granules with low dust content and excellent spreading characteristics.

Q4: What are the key after-sales services provided?

A4: LANE provides comprehensive services including detailed operator training, on-site commissioning supervision, a full package of technical documentation, and a global network for spare parts and technical support.

Q5: Is the production process environmentally compliant?

A5: The design inherently focuses on efficiency and closed-loop systems where possible. By-product streams like magnesium chloride can often be concentrated and marketed for industrial applications, and our thermal systems are designed for clean, efficient combustion.

Conclusion: Building the Future of Fertilizer

LANE Heavy Industry’s SOP fertilizer from mineral production line represents the future direction of the fertilizer manufacturing industry, combining efficiency, quality, and environmental protection. Success in this competitive market depends on deploying production technology that is reliable, efficient, and capable of producing a superior product. By integrating world-class machinery into a seamless process flow, we provide producers with the robust, high-yield foundation needed to profitably meet the world’s growing demand for premium potash.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment