Designing an Efficient SOP Fertilizer Low Dust Production Line: A LANE Heavy Industry Guide

Introduction: The Imperative for Low Dust SOP Production

The modern work culture promotes the safety of workers above all else. There are lots of strict environmental protection policies placed on the fertilizer industry to protect workers from harm. Dust is one of the major pollutants that harms workers while they are doing their work. Sulfate of Potash (SOP) is very popular among high-value cash crop farmers for its low chloride, high potassium, and sulfur content. But its production generates dust. This dust generation leads to product loss, safety hazards, equipment wear, and environmental non-compliance. An SOP fertilizer low dust production line is the solution for this problem.

At LANE Heavy Industry, we believe that a modern SOP fertilizer low dust production line is not a luxury; it is a fundamental requirement for sustainable, profitable, and responsible manufacturing. We have designed an efficient SOP fertilizer low dust production line which integrates advanced low-dust technology.

Core Challenges in Traditional SOP Fertilizer Production

Traditional SOP granulation lines struggle with dust at multiple points:

- Raw Material Handling: Fine SOP powder is dusty. During conveying, dust pollution occurs.

- Granulation & Drying: Rotary drums and dryers can generate dust through attrition and airflow.

- Screening & Size Separation: Vibrating screens are a primary source of airborne particles.

- Cooling: The thermal shock and tumbling in coolers can break down granules, creating fines.

- Packaging: Open hoppers and manual bagging stations create visible dust plumes.

Addressing these points one by one is very ineffective. An efficient SOP fertilizer low dust production line uses system-wide controls from the very beginning.

The LANE Blueprint: Key Stages of an Efficient Low Dust Line

LANE Heavy Industry designs production lines that are built for pollution control and efficient use of resources. Here is the step-by-step breakdown of the SOP fertilizer low dust production line:

Intelligent Raw Material Reception & Handling

We use enclosed conveying systems such as bucket elevators with sealed casings, enclosed double screw conveyors, and enclosed belt conveyors. Our conveying systems are carefully engineered with air-to-material ratios to prevent both blockages and excessive dusting. These systems are an integral part of the overall SOP fertilizer low dust production line, ensuring clean, efficient handling from the very start.

Precision Mixing and Granulation: The Heart of Dust Control

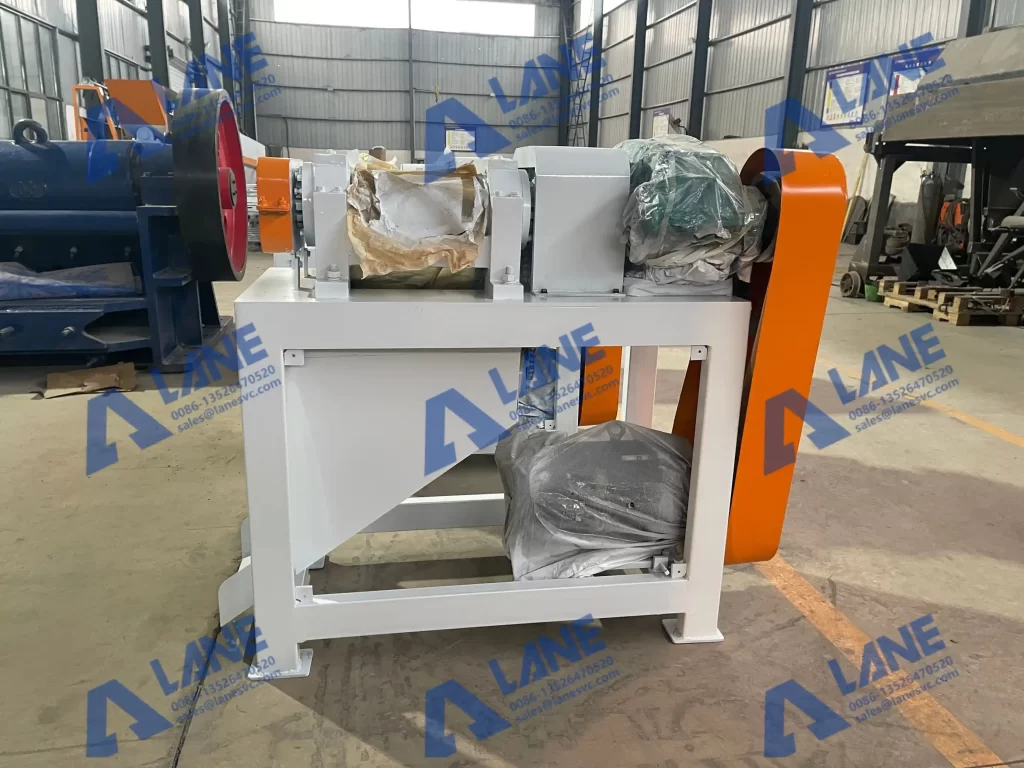

Most of the dust is generated in the mixing area. Our horizontal mixer is an enclosed system that doesn’t let any dust leak out. You can also add your formulation in this area. We utilize advanced rotary drum granulators or double-roll compaction granulators for granulation. For a small factory, double roller granulators are effective. We ensure proper feed control and consistent roller pressure to produce dense, low-fine flakes. Our drum granulators are designed with optimal drum speed, lifters, and spray systems to ensure uniform coating of seed particles, promoting even layer growth and minimizing the creation of fine, dusty agglomerates.

Efficient Drying & Gentle Cooling

LANE’s rotary dryers are designed for maximum heat efficiency. They use minimal air velocity to reduce the risk of fine particle carry-over into the exhaust system. Then the granules are sent to the rotary coolers that use controlled, ambient airflow to gently bring down the product temperature without causing thermal stress and granule breakdown, which is a major source of post-process dust.

Sophisticated Screening and Recycling

Our multi-deck vibrating screeners or rotary screens are fully enclosed. Fine particles (<1mm) and oversized granules are separated and sent to a crusher to be recycled back to the production line. LANE’s design ensures these materials are efficiently and automatically returned to the granulator via enclosed conveyors. This closed-loop system not only controls dust but also maximizes raw material utilization, boosting overall yield.

The Coating & Conditioning Stage

Coatings eliminate dust from forming on the granules. This is the signature step in an SOP fertilizer low dust production line. The granules are sent to a dedicated rotary coating drum. This drum applies a uniform layer of anti-caking and dust-suppression agents (e.g., specialized oils or surfactants) onto the cooled granules. This coating seals the surface of the granules, prevents moisture absorption, and reduces the generation of dust during subsequent handling, storage, and application by the end customer.

Automated, Dust-Tight Packaging

Finally, after coating, the granules are sent to the fully automated packaging system. We use enclosed conveyors to send the granules into the automatic packing machine. This creates a near-hermetic seal between the bag and the filling spout. It creates a clean, professional packaging area.

The Tangible Benefits of a Low Dust SOP Line

Investing in a LANE-designed system delivers measurable returns:

| Benefit Category | Specific Outcomes |

| Economic | Increased product yield (up to 3-5%), reduced raw material waste, lower maintenance costs from abrasive dust, and reduced filter replacement. |

| Operational & Safety | Improved plant hygiene, enhanced worker safety (reduced respiratory risks and slip hazards), and lower risk of combustible dust incidents. |

| Quality & Market | Consistent, hard, dust-free granules improve product appearance, flowability, and consumer appeal, strengthening brand reputation. |

| Environmental | Easier compliance with air quality regulations, reduced environmental footprint, and a cleaner community relationship. |

Conclusion: Investing in Clean, Efficient Production

Designing an efficient SOP fertilizer low dust production line requires complex engineering and efficient machines. The design must balance chemistry, mechanical design, and airflow dynamics. LANE Heavy Industry leverages decades of experience to deliver an integrated solution for a dust-free SOP production line where dust control is a core mechanism, not an add-on. The result is a production asset that is not only cleaner and safer but also more profitable and sustainable in the long term.

FAQ: Your Questions on SOP Fertilizer Low Dust Lines, Answered

Q1: Is a low dust production line significantly more expensive than a standard line?

A1: While the initial capital investment is moderately higher due to enclosed systems, advanced coating units, and integrated filtration, the Return on Investment (ROI) is compelling. For an SOP fertilizer low dust production line, savings from increased yield, reduced product loss, lower maintenance, and avoided regulatory fines typically pay back the premium within a short operational period.

Q2: Can LANE retrofit an existing SOP production line to be low dust?

A2: Yes, absolutely. LANE specializes in audits and targeted retrofits for SOP fertilizer projects. We can identify the key dust generation points (often screening, transfer points, and packaging) and implement modular upgrades, such as adding enclosed conveyors, high-efficiency cyclones, bag filters, or a coating drum, to transform a conventional system into a high-performance SOP fertilizer low dust production line.

Q3: How does the coating affect the agronomic properties of the SOP fertilizer?

A3: The coatings used in our lines are specifically formulated for fertilizers. They are inert, non-toxic, and applied in minute quantities (typically 0.2–0.5%). They do not affect the nutrient availability or soil interaction of the SOP. Their sole purpose is to seal the granule surface and improve physical handling properties in an SOP fertilizer low dust production line.

Q4: What is the single most important stage for dust control in SOP production?

A4: It’s a systemic effort, but if one stage were to be highlighted, it is the combination of granulation quality and final coating. Producing a strong, uniformly-sized granule at the start minimizes fines generation throughout the process. The final coating then “locks in” the granule, providing lasting dust suppression all the way to the farmer’s field.

Q5: Does LANE provide complete, turnkey production lines?

A5: Yes. LANE Heavy Industry is a full-service provider. We offer everything from initial feasibility studies and process design, to manufacturing, automation, installation, commissioning, and operator training, delivering a complete, optimized, and low dust SOP fertilizer production line ready for operation.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment