SOP Fertilizer for Hydroponics: What It Is and Why You Need It

Introduction

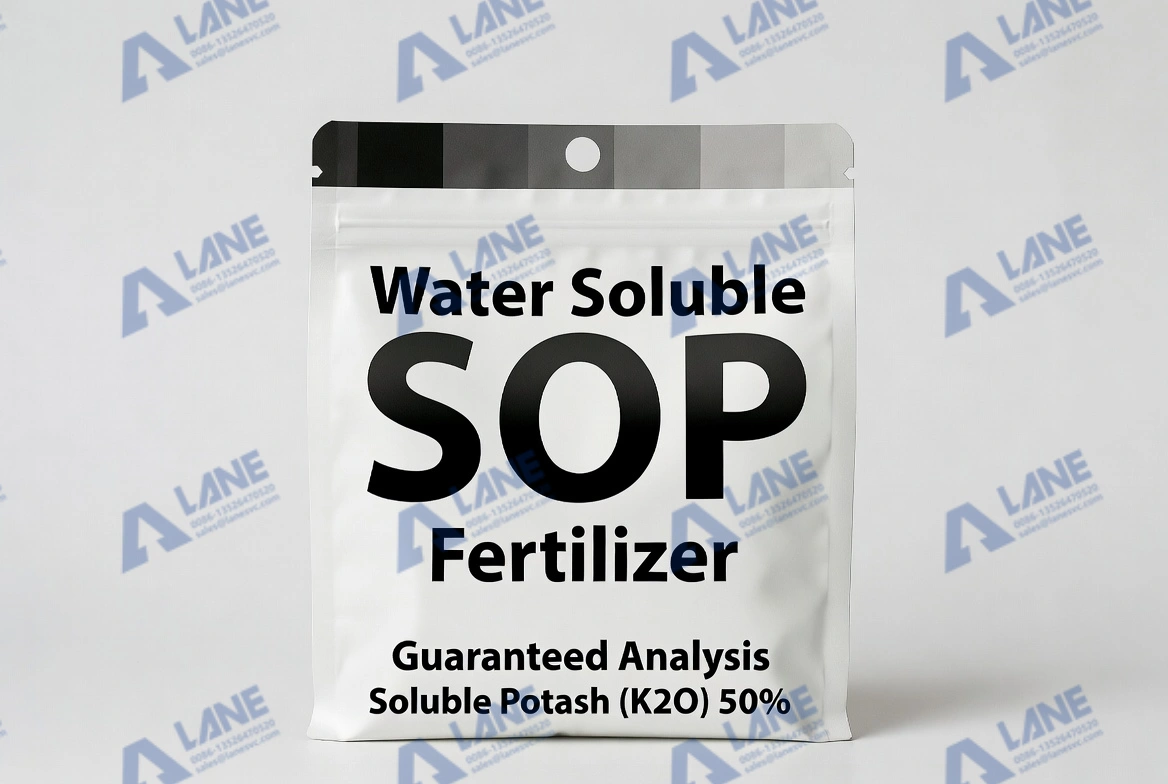

Sulfate of Potash (SOP) fertilizer is a high-purity, chloride-free nutrient source for modern agriculture. SOP fertilizer delivers 50% potassium oxide (K₂O) and 18% sulfur (S) without harmful salts. SOP fertilizer for hydroponics has become an essential element for enhancing plant growth in soilless agriculture systems. In soilless hydroponic systems, maintaining nutrient balance is critical; a slight change can have serious consequences. While NPK (Nitrogen-Phosphorus-Potassium) forms the backbone of plant nutrition, the source of these nutrients is equally important in hydroponic systems. This is where SOP fertilizer for hydroponics stands out as a superior choice for potassium delivery.

In hydroponics, where plants absorb nutrients directly from water, the purity and solubility of fertilizers dictate crop health and yield. SOP fertilizer for hydroponics stands out as it can easily be dissolved in water, ensuring rapid nutrient uptake and no residue buildup in reservoirs or root zones.

In this article, we will learn about SOP fertilizer for hydroponics and how LANE Heavy Industry’s advanced SOP fertilizer production line can help meet the growing demand for high-quality SOP fertilizer in hydroponic agriculture.

What Exactly is SOP Fertilizer?

SOP stands for Sulfate of Potash. Its chemical formula is K₂SO₄, which means it is composed of potassium (K) and sulfur (S) in sulfate form. It is a water-soluble, chloride-free potassium fertilizer. The most common potassium source is Muriate of Potash (MOP or KCl), also known as potassium chloride. SOP provides a pure source of potassium along with sulfate that won’t harm chloride-sensitive plants or accumulate salts in closed hydroponic systems.

Why Hydroponic Systems Crave SOP

Hydroponics is a controlled system. It offers unparalleled control over crops but it also removes the buffer capacity of soil. This makes nutrient selection critical, as a slight increase in salts can cause crop yield losses. SOP is highly valued for several reasons:

- Chloride-Free: Many high-value hydroponic crops (like strawberries, tomatoes, lettuce, and berries) are sensitive to chloride, which can cause toxicity, burn root tips, and negatively affect flavor and yield. SOP eliminates this risk.

- Dual-Nutrient Benefit: It delivers both potassium and sulfur in sulfate form, which can be easily absorbed by plants. Sulfur is a key component for protein synthesis, enzyme activity, and chlorophyll formation.

- Low Salt Index: SOP fertilizer for hydroponics contains less than 0.5% chloride. It doesn’t contribute to the salinity of the hydroponic system. It offers greater management flexibility and reduced stress on plants.

- Improved Quality: SOP fertilizer for hydroponics is linked to improved fruit size, stronger stems, richer colors, and enhanced taste profiles. In hydroponic systems, these qualities are directly linked to crop profitability and price.

The Critical Role of Potassium and Sulfur

- Potassium (K):Potassium is known as the quality nutrient. It is crucial for enzyme activation, photosynthesis, water regulation, and the transport of sugars and starches. In hydroponics, adequate potassium directly influences fruit development, disease resistance, and overall plant vigor.

- Sulfur (S) in Sulfate Form: Sulfur is the building block of amino acids and vitamins. The sulfate form is immediately available for plant uptake through the roots. It supports rapid growth and efficient nitrogen use.

The Importance of Production Quality: A Look at LANE Heavy Industry’s SOP Fertilizer Production Line

The purity, solubility, and physical consistency of SOP fertilizer for hydroponics is non-negotiable. Any kind of impurity can lead to clogged irrigation systems. The quality of SOP fertilizer for hydroponics depends entirely on production precision. Henan LANE Heavy Industry Machinery Technology Co., Ltd. sets the standard with its advanced production line. As a leader in fertilizer equipment manufacturing, LANE integrates R&D, production, and after-sales service to deliver consistent, high-grade SOP tailored for hydroponic use.

- Raw Material Preparation: SOP powder is precisely weighed and fed into the system.

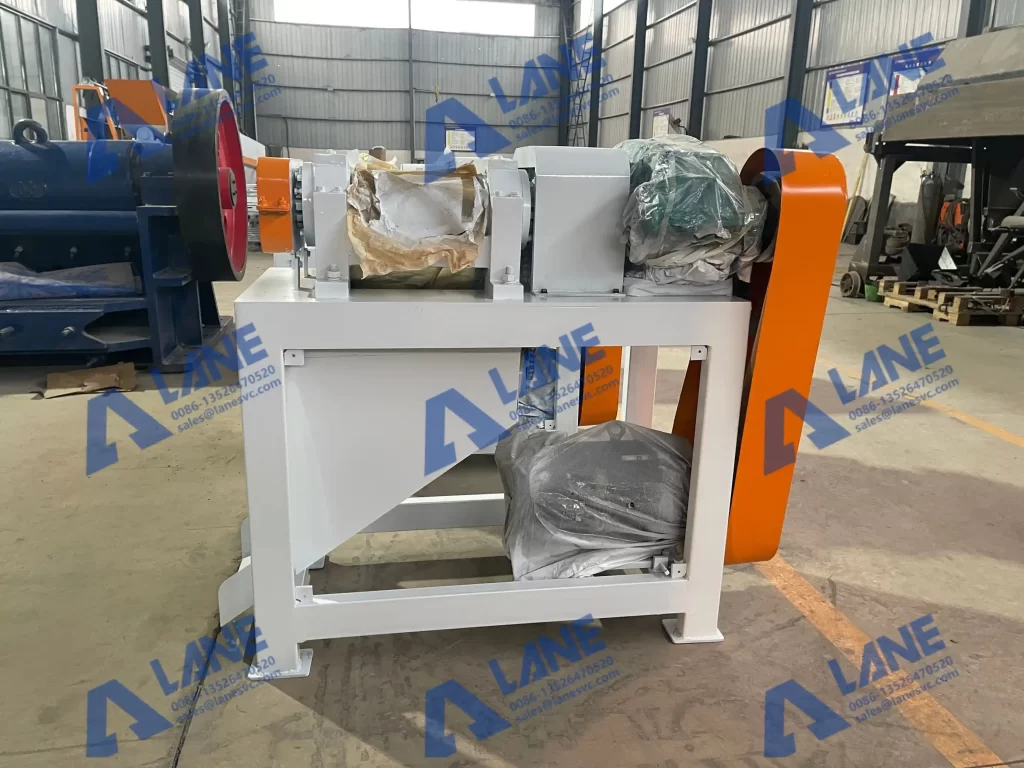

- Compaction & Granulation: The powder is passed through a heavy-duty double roller press granulator. This machine applies extreme pressure with two counter-rotating rollers to compact the fine powder into solid granules in a process known as dry granulation.

- Screening: he compressed granules are screened for on-size granules. In this process, a rotary screening machine is used. It separates on-size granules from fines and oversized granules. The oversized granules and fines are sent to the crusher and recycled into production.

- Packaging: The granules are sent to a LANE automatic packing machine which weighs the granules and packages and labels them.

By utilizing durable, precision-engineered machinery from LANE Heavy Industry, producers can create a consistent, high-purity, and dust-free SOP fertilizer for hydroponics. Hydroponic growers get a reliable fertilizer that dissolves cleanly, won’t clog sensitive drippers or misters, and delivers nutrients as promised without hidden contaminants.

How to Use SOP Fertilizer in Your Hydroponic System

SOP fertilizer for hydroponics is highly soluble and can be integrated into your nutrient regimen in the following ways.

- As Part of a Pre-Mixed Nutrient Solution: You can mix SOP with other base nutrients to create a full nutrient solution. Many commercial hydroponic base nutrients already include SOP in their formulation.

- As a Standalone Supplement: To create your custom recipes or address specific potassium deficiencies, SOP can be dissolved separately and added to the reservoir. Always dissolve it completely in a separate container of warm water before adding it to your main reservoir to prevent precipitation.

Frequently Asked Questions (FAQ)

Q1: Can I use SOP fertilizer for all my hydroponic plants?

A1: Absolutely. It is safe and beneficial for all plants. It is especially recommended for chloride-sensitive crops like tomatoes, cucumbers, peppers, strawberries, beans, and lettuce.

Q2: How is SOP different from Monopotassium Phosphate (MKP)?

A2: Both are excellent hydroponic fertilizers. MKP (KH₂PO₄) provides potassium and phosphorus, making it ideal for the flowering/fruiting stage. SOP provides potassium and sulfur, with no phosphorus. They are often used in conjunction at different growth stages.

Q3: Will SOP fertilizer change the pH of my nutrient solution?

A3: SOP has a neutral pH effect when dissolved in water and is unlikely to cause significant pH fluctuations, making it very stable in a well-managed reservoir.

Q4: Why does the manufacturing process (like LANE’s production line) matter to me as an end grower?

A4: Consistent, high-quality granulation ensures predictable solubility, uniform nutrient release, and protects your expensive hydroponic equipment from clogging. It guarantees you are getting a pure product free from physical and chemical contaminants.

Conclusion

SOP fertilizer for hydroponics is a game-changer for soilless growers. It offers a chloride-free, dual-nutrient solution that promotes plant health, maximizes yield quality, and protects your system’s integrity. Its purity, solubility, and low salt index address the unique challenges of hydroponic nutrition. By understanding what SOP is and why it’s produced to high standards, you can make an informed choice to power your hydroponic success.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment