Double Roller Granulator

Double Roller Granator is a mechanical equipment widely used in agriculture, chemical industry and other fields. It mainly uses two relatively rotating rollers to forcibly squeeze the mixed powdered materials into granules. This equipment plays an important role in the production of organic fertilizers, compound fertilizers, and other fertilizers, with advantages such as high production efficiency and good product quality.

Composition structure

The Double Roller Granulator mainly consists of the following parts:

Feeding system: responsible for conveying powdered materials into the interior of the granulator, usually including hoppers, conveyor belts, etc.

Squeezing system: consisting of two relatively rotating rollers, it forcefully squeezes materials. The surface of the roller is usually covered with wear-resistant materials to reduce wear and improve service life.

Discharge system: It discharges the pelletized material from the machine, usually including a discharge port and conveyor belt.

Control system: used to control the operating status of the machine, including start, stop, speed regulation, etc.

Lubrication system: provides necessary lubrication for various moving parts of the machine to ensure their normal operation.

Working process

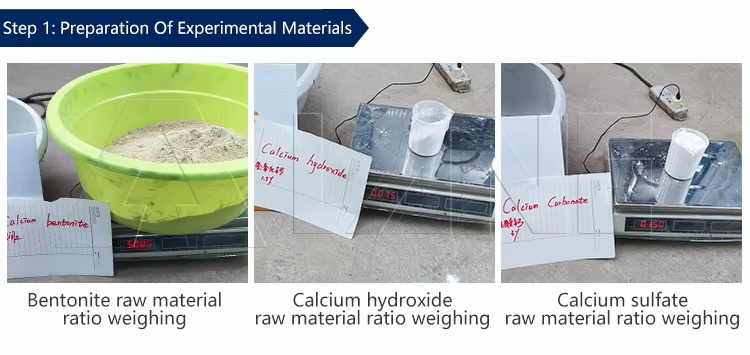

The working process of Double Roller Granulator mainly includes the following steps:

Feeding: The powdered material is transported to the interior of the granulator through the feeding system.

Squeezing: The material is forcibly squeezed between two relatively rotating rollers, gradually forming particles. The pressure and speed between the rollers can be adjusted as needed to obtain particles of different sizes and shapes.

Discharge: The pelletized material is discharged from the machine through the discharge system for subsequent processing or packaging.

Advantage

The Double Roller Granulator has the following advantages:

High production efficiency: Two relatively rotating rollers are used for extrusion, which can quickly convert powdered materials into granules and improve production efficiency.

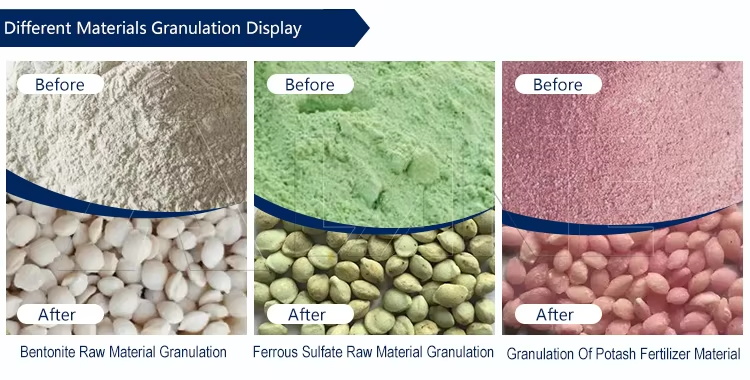

Good product quality: By adjusting the pressure and speed between the rollers, particles of different sizes and shapes can be obtained to meet the production needs of different products. Meanwhile, due to the significant pressure exerted on the material during the extrusion process, the particles formed are more compact and stable.

Wide adaptability: It can be used for granulation of various powdered materials, such as organic fertilizers, compound fertilizers, etc., with a wide range of applications.

Easy to operate: The machine has a simple structure, is easy to operate, and is easy to maintain and upkeep.

Environmental protection and energy conservation: There will be no harmful substance emissions during the production process, which meets environmental protection requirements; Simultaneously adopting energy-saving technologies to reduce energy consumption.

In summary, the Double Roller Granulator has been widely used and recognized in the agricultural field due to its high efficiency, stability, and environmental friendliness.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!