Drum Cooler

Drum Cooler for Potassium Sulphate Sop Plant.The primary purpose of a drum cooler in a SOP plant is to lower the temperature of the hot potassium sulfate particles, which are typically produced as a result of a chemical reaction or crystallization process.

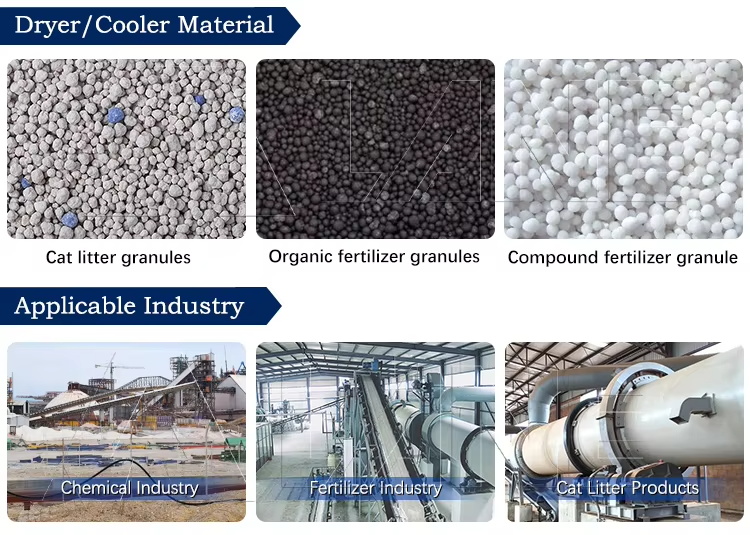

Drum Cooler is a device used for cooling granular materials, widely used in industries such as chemical, pharmaceutical, and food. It rapidly cools granular materials by rotating drums and cooling media (such as air, water, etc.), reducing their temperature and maintaining their stability.

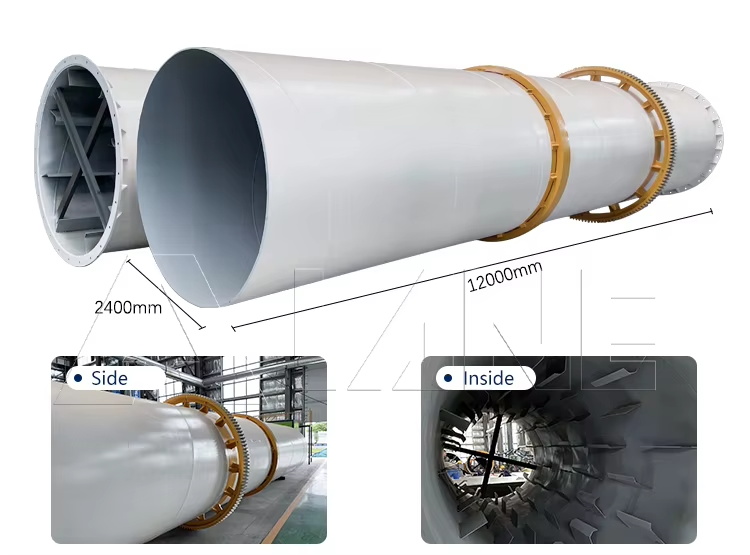

Composition Structure

Drum Cooler mainly consists of the following parts:

Feeding system: responsible for conveying granular materials to be cooled into the equipment.

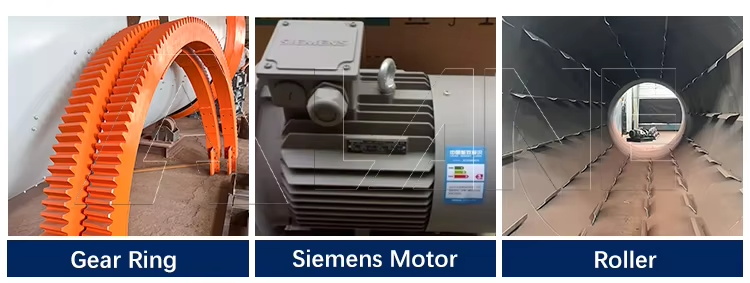

Rotating drum: driven by a motor, it continuously rolls and cools granular materials.

Cooling medium supply system: Provides cooling medium (such as air, water, etc.) to the rotating drum to cool granular materials.

Discharge system: Transport the cooled material to the outside of the equipment.

Control system: used to control the operating status and parameter settings of equipment.

Working process

Drum Cooler uses cold air as a cooling mechanism to cool materials.

During the clinker production process, the hot clinker discharged from the rotary kiln enters the rotary cooling machine cylinder through the feed inlet. Under the combined action of cylinder rotation and gravity, the material slowly moves along the cylinder wall to the lower discharge outlet.

The cold air generated by the cooling fan moves from the lower end to the upper end of the cylinder, meets the convective material, transfers heat energy from the material to the airflow, and the cooling air is discharged from the upper exhaust outlet with the heat of the material, and returns to the rotary kiln as secondary air.

The spiral blades on the inner wall continuously lift and scatter the material as the drum rotates, allowing the material to fully contact the cold air and accelerating the cooling process.

Advantage

Drum Cooler has the following advantages:

High cooling efficiency: Through sufficient contact between the rotating drum and the cooling medium, rapid cooling of granular materials can be achieved, improving production efficiency.

Good product quality: Through precise temperature control, the stability and quality of granular materials are ensured.

Wide applicability: Suitable for cooling treatment of various granular materials, such as chemical raw materials, pharmaceutical intermediates, food additives, etc.

Easy to operate: The device has a simple structure, is easy to operate, and is easy to maintain and clean.

Environmental protection and energy conservation: No harmful substances will be emitted during the cooling process, meeting environmental protection requirements; Simultaneously adopting energy-saving technologies to reduce energy consumption.

High degree of automation: Equipped with advanced control systems, it can achieve automated production and remote monitoring, improve production efficiency and management level.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!