What is SOP Fertilizer

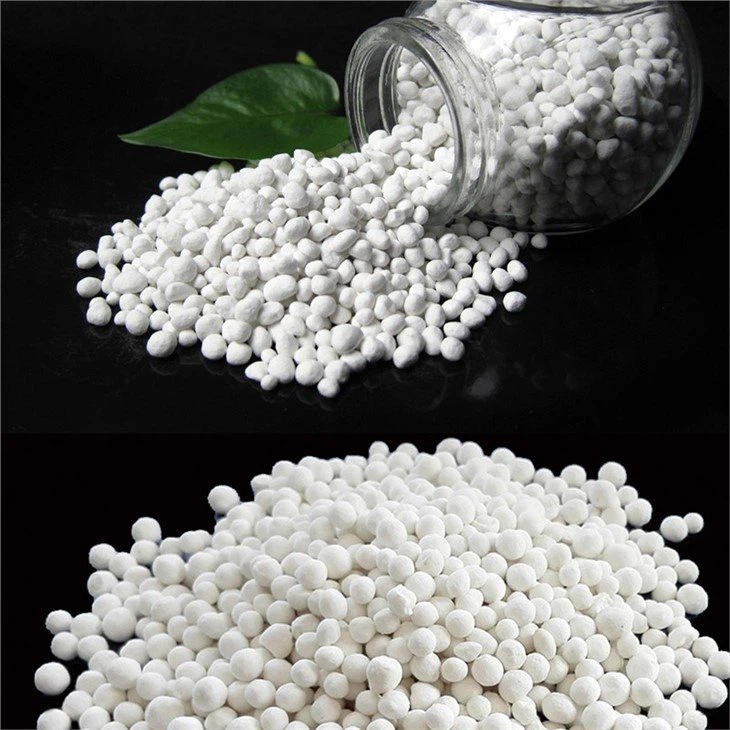

SOP fertilizer (chemical formula: K₂SO₄) contains about 50% potassium (K₂O) and 18% sulfur (S), two essential elements for plant growth. Potassium improves drought resistance, disease tolerance, and the overall strength of plant tissues, while sulfur enhances protein synthesis and chlorophyll formation.

Potassium sulfate fertilizer does not contain chloride, making it particularly suitable for crops that are sensitive to salt and alkali. Its neutral pH value ensures that the soil will not become acidic or alkaline, thereby promoting the long-term fertility and sustainability of the soil.

In the global agricultural sector, the demand for potassium sulfate fertilizer has been continuously increasing due to the expansion of the area for cultivating high-quality crops and the promotion of environmentally friendly fertilization methods.

The Production Process of SOP Fertilizer

The industrial production of SOP fertilizer typically follows a chemical reaction between potassium chloride (KCl) and sulfuric acid (H₂SO₄). The simplified reaction equation is:

The process involves two main stages:

Low-temperature reaction: KCl reacts with sulfuric acid to form potassium bisulfate (KHSO₄) and hydrogen chloride gas.

High-temperature conversion: KHSO₄ reacts with more KCl to produce potassium sulfate (K₂SO₄) and HCl gas.

The byproduct, hydrochloric acid (HCl), can be captured and reused, ensuring that the SOP fertilizer production line is efficient and environmentally responsible.

Advanced Plant Configuration: Efficiency and Sustainability

A modern SOP fertilizer production line includes several integrated systems to ensure consistent quality and safe operation:

Raw Material Handling System: Potassium chloride is transported via conveyors and elevators to the furnace feed hopper, while 98% sulfuric acid is pumped to the reaction tank.

Furnace and Reaction System: Controlled by PLC automation, KCl and H₂SO₄ react at precise ratios and temperatures to achieve maximum conversion efficiency.

HCl Absorption System: The hydrogen chloride gas is cooled and absorbed to produce industrial hydrochloric acid (30–33%), which can be sold or reused.

Cooling and Circulation System: Hot water is cooled and recirculated, minimizing waste and conserving energy.

Product Crushing and Screening System: The final potassium sulfate crystals are crushed, screened, and stored as premium-grade SOP fertilizer.

This closed-loop design significantly reduces pollution, waste, and energy consumption—qualities that align with LANE’s mission to promote green fertilizer manufacturing technologies.

Key Advantages of SOP Fertilizer Production

1.Chloride-Free Potassium Source

Unlike MOP, SOP fertilizer does not contain chloride, which can damage sensitive crops such as tobacco, tea, grapes, and citrus. It provides high-purity potassium that enhances flavor, color, and storage quality in fruits and vegetables.

2.Dual Nutrient Function

SOP fertilizer supplies both potassium and sulfur—two macronutrients essential for high-yield crops. This dual benefit improves overall crop vigor, boosts oil and protein synthesis, and strengthens plant immunity.

3.Environmentally Friendly Manufacturing

The SOP fertilizer production line minimizes environmental impact through acid gas recycling and wastewater neutralization systems. LANE’s proprietary process ensures zero discharge and maximum resource recovery.

4.Long-Term Economic Benefit

While initial investment may be higher than traditional NPK blending, the stable market value of SOP fertilizer and its efficiency in premium crop cultivation offer long-term profitability.

LANE’s Expertise in SOP Fertilizer Production Lines

LANE has decades of experience designing and manufacturing complete SOP fertilizer production lines for global clients. The company integrates engineering design, fabrication, installation, and training services into one seamless solution.

Key highlights of LANE’s SOP fertilizer system include:

High Automation: PLC-controlled operations for stable output and precise reaction ratios.

Energy Optimization: Efficient heat recovery and gas absorption systems reduce fuel costs.

Customizable Capacity: Standard 10,000 MTPA models, expandable via modular parallel lines.

Turnkey Support: From project feasibility study to installation and commissioning, LANE provides full lifecycle technical service.

Global Reach: Projects successfully delivered to Southeast Asia, the Middle East, and Africa with strong after-sales support.

LANE’s professional team ensures that every SOP fertilizer production line is tailored to local conditions—whether the client requires a compact plant footprint, specific acid recovery design, or fully automated control.

Economic and Environmental Value

Building a potassium sulfate (SOP) fertilizer production plant not only brings significant economic benefits, but also contributes to the achievement of the Sustainable Development Goals (SDGs). LANE Company, through its optimized process, can save energy and reduce emissions for each ton of potassium sulfate produced, and provide a reliable potassium source for global food security.

LANE integrates industrial engineering technology with agricultural concepts, aiming to transform raw materials into high-value fertilizers, thereby benefiting farmers and the planet.

Building a Sustainable Future with SOP Fertilizer

Potassium sulfate (SOP) fertilizer is not merely a source of nutrients for crops; it is also a crucial component of sustainable food production. With its chlorine-free formula, dual nutritional advantages, and compatibility with precision agriculture, potassium sulfate fertilizer is becoming an indispensable part of global agriculture.

LANE’s advanced potassium sulfate fertilizer production line solutions help enterprises confidently, efficiently, and sustainably enter this booming market. LANE, with its innovative spirit, environmental responsibility, and professional engineering technology, continuously leads the transformation of the fertilizer industry, turning simple chemical reactions into a global agricultural revolution.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment