The Complete Guide to Manufacturing SOP Fertilizer Granules: From Raw Material to Coated Product

Introduction: The Rise of Premium SOP Fertilizer Granules

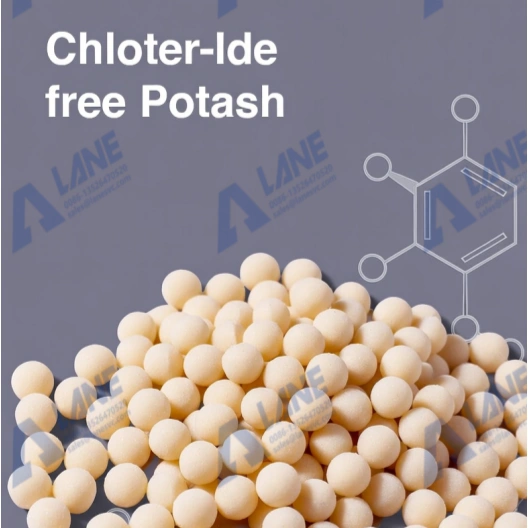

Sulfate of Potash (SOP) is a premium potassium fertilizer that delivers potassium alongside sulfur in sulfate form. It is not the most common potassium source, but it is the main potassium source for chloride-sensitive crops like fruits, vegetables, nuts, and tobacco.

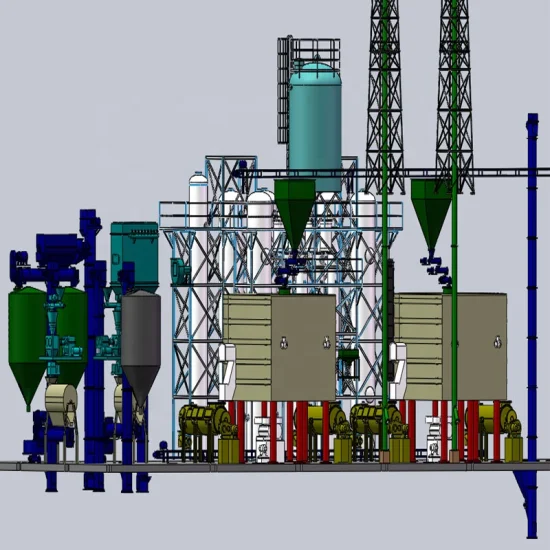

SOP fertilizer granules are created from SOP powder or crystals. Granules are valued more because of their uniform, dust-free, and readily applicable form. This process is achieved through a dedicated SOP fertilizer production line. SOP fertilizer granules represent a premium product which helps farmers earn higher crop prices. For this, the fertilizer granules must be uniform and contain consistent nutrients. This article will guide you through the entire manufacturing journey with the help of expert fertilizer machine manufacturer LANE Heavy Industry.

Understanding SOP: Why the Granule Form is King

After chemical reaction or synthesis, raw SOP (K₂SO₄) is in powder or crystal form. These forms are also effective, but they come with handling challenges. They are dusty, difficult to spread evenly, and can cause segregation in bulk blends. SOP fertilizer granules solve these problems. The granulation process creates consistent, uniform particles that are:

Dust-Free:The granules are dust-free. It improves the work environment and reduces product loss.

Easy to Handle & Spread:They are easy to handle and spread. You can apply them uniformly across the fields.

Resistant to Caking: The moisture of the granules is controlled in the production line. They don’t cause caking and maintain their properties during storage.

Suitable for Blending: They are suitable for complex fertilizer mixes.

Controlled Release: You can coat them for a higher shelf life.

Stage 1: Raw Material Handling & Preparation

The granulation production process begins after acquiring raw SOP. After that, they are sent to the dynamic batching feeder. This machine acts as temporary storage and releases the raw material according to the input of the operator. These raw SOP crystals or powder are sent to the crusher to achieve a uniform fine powder. This is essential for the granulation stage. They can then be sent to the mixer where you can add a binding agent or micronutrients. LANE Heavy Industry provides durable crushers and precision mixers for these operations.

Stage 2: The Granulation Heart – Compaction & Granulation

For SOP fertilizer granules, the dry compaction granulation method is the most common and effective. SOP has limited natural binding properties when wet, so compaction has a greater effect on the granulation process than the wet method

Compaction:The mixed dry SOP powder is fed into a double roller granulator. Inside this machine, two synchronized, high-pressure rollers compress the powder into a solid, dense sheet or flakes. The pressure from the rollers creates natural adhesion between the particles without the need for significant moisture.

LANE Heavy Industry’s double roller press granulators are engineered for producing high pressure and continuous operation. The granulator features wear-resistant roller shells and precise gap control, which are vital for producing strong SOP fertilizer granules.

Stage 3: Post-Granulation Processing

The newly formed granules are “green” and require finishing. The newly formed granules need further refining before they can be sent to the packing machine.

- Screening:The granules pass through a rotary drum screen or vibrating screen to separate the on-size product from oversized granules or fines. Oversized granules and fines are then crushed and recycled

- Polishing & Dedusting:A rotary polisher might be used to round off sharp edges. This process reduces dust and improves the final product’s appearance and flowability.

- Drying & Cooling: The dry process minimizes the moisture of the granules, while the cooling process brings the granules down to ambient temperature. It stabilizes the granules for the storage process.

Stage 4: Coating, Packaging, and Quality Assurance

To increase the shelf life and value of SOP fertilizer granules, you can do:

- Coating: In a rotary coating drum, a thin layer of anti-caking agent (e.g., oils, polymers) or dust suppression coating is evenly applied. You can also add micronutrients in this process. This step guarantees long-term storage stability and perfect flow.

- Packaging: The finished granules are then conveyed into automated weighing and bagging systems for packaging. After packaging, they are ready for the market.

- Quality Control: Throughout the line, samples are tested for granule strength (hardness), size distribution, nutrient content (K₂O), and moisture levels to ensure they meet the formulation.

The LANE Heavy Industry Advantage: Precision Engineering for Premium Output

Building a reliable SOP fertilizer granule line requires machinery that can withstand abrasion, pressure, corrosion, and continuous operation. LANE Heavy Industry has been creating fertilizer production lines for over 20 years. Their experience in the fertilizer industry is undeniable. Our machinery, from heavy-duty Double Roller Granulators to efficient Rotary Dryers, Coolers, and Screening Systems, is designed with:

- High Wear Resistance:They are made with corrosion-resistant material that can withstand the continuous operation of abrasive SOP materials.

- Process Synchronization:All the machines in the production line are designed to work together as a harmonized system. It increases efficiency and minimizes energy consumption.

- Robust Construction: The machines are built for 24/7 industrial operation with easy access for maintenance.

- Customizable Design: The production line can be designed according to the raw material and needs of the operator. We can also tailor the capacity requirements and factory layouts.

By choosing LANE Heavy Industry as your production line manufacturer, you effectively eliminate the hassle of design, training, machinery sourcing, and after-sales service worries. LANE provides a full turnkey solution for the SOP production line. With LANE, your SOP fertilizer granule production line will have compatibility, reduced downtime, and consistent production.

Frequently Asked Questions (FAQ)

Q1: Why is compaction granulation preferred over steam granulation for SOP?

A:SOP lacks the plasticity of materials like monoammonium phosphate (MAP) or diammonium phosphate (DAP). Wet granulation (using steam or water) is inefficient as SOP does not form stable granules easily upon drying. Dry compaction uses high mechanical pressure to fuse particles, making it the most effective and energy-efficient method for SOP fertilizer granules.

Q2: What is the typical production capacity of a LANE SOP granulation line?

A: LANE Heavy Industry designs lines to be highly scalable. Capacities can range from small-scale lines of 5-10 tons per hour to large-scale industrial systems producing 30+ tons per hour of finished SOP fertilizer granules. The exact configuration depends on customer investment and market goals.

Q3: How important is the coating process for SOP granules?

A: While not always mandatory, coating is highly recommended for premium-grade products. An anti-caking coating prevents granules from sticking together during storage and transport, especially in humid climates. It ensures the product remains free-flowing from the bag to the spreader, delivering optimal value to the end-user.

Q4: Can the same production line produce other types of fertilizer granules?

A: A well-designed compaction granulation line is versatile. With adjustments to roll pressure, screen sizes, and conditioning, it can often also produce other non-chloride potash fertilizers like potassium nitrate (KNO3) granules or NPK blends based on powdered materials. LANE Heavy Industry can advise on multi-purpose line configurations.

Q5: What are the key quality indicators for finished SOP fertilizer granules?

A: The main quality parameters are:

- Granule Strength (Hardness):>30N is typically desired to withstand handling.

- Size Uniformity:A narrow range (e.g., 2-4 mm) with minimal fines.

- Nutrient Content:Typically 50-52% K₂O.

- Moisture Content:Very low (<1.0%) to prevent caking.

- Dust Content:Minimal, as achieved through proper polishing and coating.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment