A Step-by-Step Guide to Producing SOP Fertilizer for Nuts and Tea Cultivation

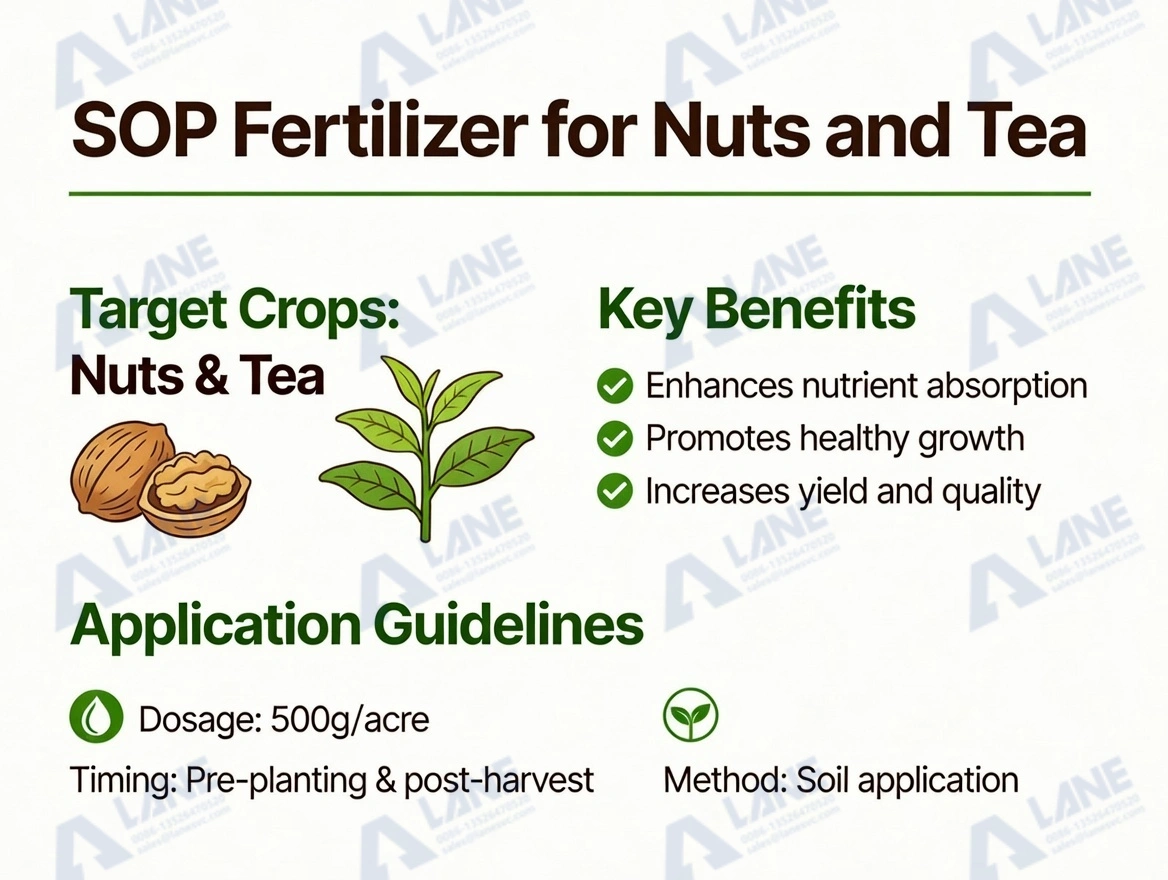

Nuts (almonds, walnuts, pecans) and tea are high-value, chloride-sensitive crops. They rely on balanced nutrition to thrive. SOP fertilizer for nuts and tea is known for its high potassium content and minimal chloride content. This makes it ideal for crops which are sensitive to chloride. It supports plump nut kernels, tender tea leaves, and rich flavor compounds. Growers who aim to produce their own SOP fertilizer for nuts and tea to ensure control over quality, purity, and cost need a reliable production line and clear, step-by-step processes.

LANE Heavy Industry, a leader in fertilizer machinery, offers modular, efficient SOP production lines tailored to nut and tea growers, making it easy to produce consistent, high-quality SOP fertilizer for nuts and tea at any scale.

What is SOP Fertilizer?

Sulfate of Potash (SOP) is a premium source of potassium and sulfur. These two essential nutrients support healthy crop growth. The most common source of potassium is Muriate of Potash (MOP), which contains up to 47% chloride. SOP fertilizer for nuts and tea provides 50-52% potassium oxide (K₂O) and 17-18% sulfur with less than 1% chloride. This low chloride content makes it perfect for plants that are sensitive to chloride toxicity, such as tea plants and certain nut trees like almonds, walnuts, and pistachios. SOP fertilizer for nuts and tea promotes plant growth, enhances flower and fruit development, and improves resistance to diseases and nature.

Why SOP Fertilizer for Nuts and Tea?

Nuts and tea plants both thrive in environments with adequate potassium. Potassium enhances leaf quality and promotes better flavor and aroma for tea plants. For nut trees, potassium helps with nutrient absorption, enhances fruit quality, and boosts overall crop yield. The non-chloride nature of SOP fertilizer is particularly beneficial for these crops. By utilizing SOP fertilizer for nuts and tea, farmers can expect healthier crops, higher yields, and improved quality of produce.

SOP Fertilizer Production Process

The production of SOP fertilizer is a multi-step process. It involves several chemical reactions and mechanical operations.

- Step 1: Raw Material Sourcing

The primary raw materials used in the production of SOP fertilizer are potassium chloride (KCl), sulfuric acid (H₂SO₄), and water. The quality of the raw materials will determine the quality of the end fertilizer. High-quality potassium chloride and sulfuric acid are essential for high potassium content in the final SOP fertilizer.

- Step 2: Crushing and Grinding

In the next step, the potassium chloride is crushed and ground to a fine powder. LANE Heavy Industry machinery provides efficient grinding systems that ensure uniform particle size. Grinding the potassium chloride properly is critical for ensuring that the chemical reaction with sulfuric acid occurs efficiently.

- Step 3: Chemical Reaction

The next step is the reaction of potassium chloride with sulfuric acid. This reaction produces potassium sulfate (K₂SO₄) and hydrochloric acid (HCl). The equation for the reaction is:

2KCl + H₂SO₄ → K₂SO₄ + 2HCl

LANE uses state-of-the-art Mannheim furnace reactors to carefully control temperature and pressure conditions. This ensures that the reaction produces high-purity potassium sulfate with minimal contaminants. This is one of the most crucial steps in producing high-quality SOP fertilizer for nuts and tea.

- Step 4: Separation and Purification

After the chemical reaction, the resulting mixture contains both potassium sulfate and hydrochloric gas. LANE Heavy Industry provides advanced filtration and separation equipment that efficiently removes the hydrochloric gas and creates hydrochloric acid as a by-product. This ensures that the final SOP fertilizer contains minimal contaminants and is ideal for agricultural use. After that, the SOP fertilizer cake is cooled and ground with LANE coolers and crushers.

- Step 5: Granulation and Drying

Once purification is done, the material undergoes granulation. Granulation helps achieve a uniform size and texture. LANE uses a Double Roller Granulator for compact granulation. This ensures that the SOP fertilizer particles are evenly shaped. After granulation, the product is screened to separate on-size granules from fines and oversized granules. They are sent to be crushed and recycled back to the granulator. This ensures a closed-loop process.

- Step 6: Packaging

The final step in SOP fertilizer production is packaging. The granulated SOP fertilizer is carefully weighed, packed into bags, and labeled according to the specifications for export or domestic use. LANE Heavy Industry’s automated packaging systems streamline this process, ensuring that the final product is properly packaged and sealed for delivery to customers.

The Role of LANE Heavy Industry Machinery in SOP Fertilizer Production

LANE Heavy Industry has over 20 years of experience in producing fertilizer machinery. Our advanced machinery and equipment, including reactors, crushers, granulators, and packaging systems, ensure that each step of the production process is optimized for maximum efficiency. Our technologies help improve product quality, reduce operational costs, and increase production capacity. For those looking to produce SOP fertilizer for nuts and tea on a large scale, we offer robust, reliable, and cost-effective solutions that ensure success in the marketplace.

Benefits of SOP Fertilizer for Nuts and Tea

SOP fertilizer for nuts and tea provides a host of benefits:

- Enhances Potassium Levels: It enhances potassium levels. Potassium is vital for photosynthesis and overall plant metabolism. SOP fertilizer ensures that nuts and tea plants have the nutrient for optimal growth.

- Minimizes Chloride Toxicity: SOP fertilizer for nuts and tea contains very low chloride (less than 1%) levels. This is crucial for plants like tea and nuts which are highly sensitive to chloride-induced damage.

- Improves Fruit and Leaf Quality: SOP promotes better fruit yield in nut trees and enhances leaf quality in tea plants. This leads to superior produce.

- Boosts Disease Resistance: By promoting strong roots, SOP fertilizer helps improve the plant’s ability to resist pests and diseases.

Key Considerations for Efficient Production

Efficient SOP fertilizer production requires attention to detail in every step of the process.

- Raw Material Quality: The most critical part is getting high-quality potassium chloride and sulfuric acid. This ensures optimal product quality.

- Temperature Control: Our reactors are made for control. Proper temperature control in reactors ensures that the chemical reaction goes smoothly and produces the desired potassium sulfate.

- Granulation and Screening: The right particle size is essential for high-quality granules that provide consistent nutrients throughout the farmland.

- Equipment Maintenance: Regular maintenance of machinery, especially crushers and granulators, ensures uninterrupted production and high operational efficiency.

Conclusion

Producing your own SOP fertilizer for nuts and tea is the key to unlocking premium crop quality, controlling costs, and ensuring nutrient consistency. It is a complex but rewarding process. By following the step-by-step guide outlined above, growers can produce pure, chloride-free SOP fertilizer for nuts and tea that supports plump nut kernels, tender tea leaves, and rich flavors. LANE Heavy Industry’s SOP production line makes this process simple, efficient, and reliable.

FAQ

Q1: What is the best fertilizer for nuts and tea plants?

A1: SOP fertilizer is considered one of the best fertilizers for both nuts and tea plants due to its high potassium content and low chloride levels. It promotes healthy plant growth and improves fruit and leaf quality.

Q2: How does SOP fertilizer differ from MOP fertilizer?

A2: SOP fertilizer contains potassium sulfate and sulfur, while MOP fertilizer contains potassium chloride. The primary difference is that SOP has much lower chloride content, making it more suitable for chloride-sensitive crops like tea and nuts.

Q3: How does SOP fertilizer benefit tea cultivation?

A3: SOP fertilizer improves the quality of tea leaves, enhances aroma and flavor, and supports the plant’s resistance to diseases, all of which contribute to higher-quality tea production.

Q4: What role does LANE Heavy Industry play in SOP fertilizer production?

A4: LANE Heavy Industry provides advanced machinery that ensures the efficient and high-quality production of SOP fertilizer. Their equipment optimizes every stage of the process, from crushing to packaging.

Q5: Is SOP fertilizer more expensive than MOP fertilizer?

A5: Yes, SOP fertilizer is generally more expensive than MOP fertilizer, but its benefits, such as higher potassium availability and lower chloride content, make it a preferred choice for crops like nuts and tea.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!

Write a Reply or Comment